Exploring the Different Types of Hydraulic Cylinders Used in Maritime Ports

2025-08-05

Exploring the Different Types of Hydraulic Cylinders Used in Maritime Ports

Table of Contents

- 1. Introduction to Hydraulic Cylinders in Maritime Ports

- 2. Importance of Hydraulic Cylinders in Port Operations

- 3. Types of Hydraulic Cylinders

- 3.1 Single-Acting Hydraulic Cylinders

- 3.2 Double-Acting Hydraulic Cylinders

- 3.3 Telescopic Hydraulic Cylinders

- 3.4 Custom Hydraulic Cylinders

- 4. Applications of Hydraulic Cylinders in Maritime Ports

- 5. Key Features of Hydraulic Cylinders

- 6. Maintenance of Hydraulic Cylinders

- 7. Challenges in Hydraulic Cylinder Operations

- 8. The Future of Hydraulic Technology in Maritime Ports

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Hydraulic Cylinders in Maritime Ports

In the bustling environment of maritime ports, the efficiency and reliability of equipment are paramount. **Hydraulic cylinders** play a crucial role in these operations, acting as the backbone of various machinery used in loading, unloading, and transporting goods. They convert hydraulic energy into mechanical force, allowing for precise control and powerful movements. This article explores the different types of hydraulic cylinders utilized in maritime ports, their applications, and the importance of proper maintenance and care.

2. Importance of Hydraulic Cylinders in Port Operations

The significance of hydraulic cylinders in port operations cannot be overstated. They allow for smooth and safe handling of heavy containers and equipment, facilitating the flow of goods and enhancing overall operational efficiency. Here’s why hydraulic cylinders are indispensable in maritime ports:

- **Enhanced Efficiency**: Hydraulic systems provide powerful and swift movements, significantly reducing loading and unloading times.

- **Safety**: By improving control over heavy machinery, hydraulic cylinders help minimize accidents and ensure a safer working environment for dockworkers.

- **Versatility**: They can be used in various applications, from cranes and forklifts to gate operations and fluid handling systems.

- **Durability**: Designed to withstand harsh marine environments, hydraulic cylinders offer longevity and reliability, reducing downtime and maintenance costs.

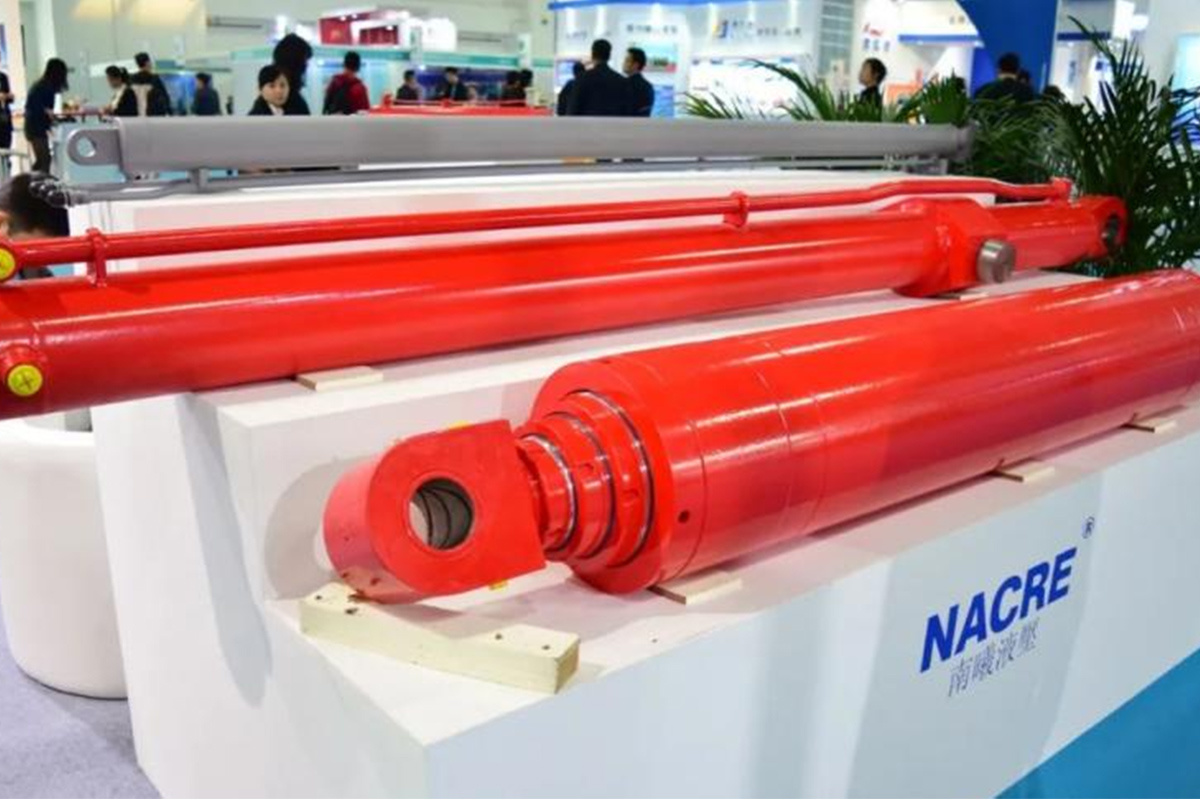

3. Types of Hydraulic Cylinders

Hydraulic cylinders come in various types, each designed for specific applications and operational requirements. Understanding these types is essential for selecting the right cylinder for a given task.

3.1 Single-Acting Hydraulic Cylinders

Single-acting hydraulic cylinders are equipped with one port for hydraulic fluid, allowing force to be applied in one direction only. They are ideal for applications where the return stroke is caused by gravity or an external force. Common uses in maritime ports include:

- Dock levelers

- Tipping gear for trailers

- Cranes for lifting operations

3.2 Double-Acting Hydraulic Cylinders

Double-acting hydraulic cylinders feature two ports, enabling them to exert force in both directions. This design allows for more versatile applications, making them suitable for heavy-duty operations that require constant movement. They are commonly used in:

- Container handling equipment

- Hydraulic presses

- Ship unloading systems

3.3 Telescopic Hydraulic Cylinders

Telescopic hydraulic cylinders consist of multiple sections that extend and retract, providing a longer stroke in a compact form. These cylinders are particularly useful in applications where space is limited but extended reach is required. In maritime ports, they are often found in:

- Container cranes

- Lift systems for maintenance

- Stackers for high-density container storage

3.4 Custom Hydraulic Cylinders

Some port operations may require specialized solutions that standard cylinders cannot meet. Custom hydraulic cylinders are tailored to fit specific needs, ensuring optimal performance and efficiency. These may include:

- Unique mounting configurations

- Specialized materials for corrosive environments

- Enhanced sealing systems for increased longevity

4. Applications of Hydraulic Cylinders in Maritime Ports

Hydraulic cylinders have extensive applications in maritime ports, aiding in various operations. Let's explore some key applications:

- **Loading and Unloading**: Hydraulic cylinders facilitate the movement of containers on and off ships, ensuring rapid turnaround times.

- **Crane Operations**: Both fixed and mobile cranes utilize hydraulic cylinders for lifting and positioning cargo, allowing for precision in high-stakes environments.

- **Gate Controls**: Hydraulic systems manage the opening and closing of gates, providing security and access control in port facilities.

- **Maintenance Activities**: Hydraulic cylinders are essential in the maintenance of port equipment, providing the necessary force for repairs and adjustments.

5. Key Features of Hydraulic Cylinders

When selecting hydraulic cylinders, it's crucial to consider various features that can enhance their performance in maritime environments. Key features to look for include:

- **Corrosion Resistance**: Given the harsh marine environment, cylinders should be constructed from materials that resist corrosion.

- **Sealing Systems**: High-quality seals prevent leaks and contamination, enhancing reliability and longevity.

- **Pressure Ratings**: Choosing cylinders with appropriate pressure ratings ensures safe and effective operation under load.

- **Temperature Tolerance**: Cylinders should be capable of operating effectively across a range of temperatures, especially in varying weather conditions.

6. Maintenance of Hydraulic Cylinders

Regular maintenance of hydraulic cylinders is essential to ensure their optimal performance and longevity. Here are some best practices for maintaining hydraulic cylinders in maritime ports:

- **Routine Inspections**: Regularly check for signs of wear, leaks, and damage. Early detection can prevent costly repairs.

- **Fluid Quality Checks**: Ensure that hydraulic fluid is clean and at the correct levels to maintain system efficiency.

- **Seal Replacement**: Replace seals periodically to prevent leaks and maintain pressure integrity.

- **Environmental Protection**: Utilize protective covers or coatings to shield cylinders from saltwater and debris.

7. Challenges in Hydraulic Cylinder Operations

While hydraulic cylinders are vital for port operations, they face several challenges:

- **Environmental Impacts**: The marine environment can lead to accelerated wear and tear on hydraulic components.

- **Operational Stress**: High loads and continuous operation can increase the likelihood of mechanical failures.

- **Fluid Contamination**: Contaminants in hydraulic fluid can compromise system performance and lead to costly repairs.

8. The Future of Hydraulic Technology in Maritime Ports

As technology advances, the future of hydraulic systems in maritime ports looks promising. Innovations such as smart hydraulic systems, which utilize sensors and IoT technology for monitoring and automation, are on the horizon. These advancements will enhance operational efficiency, reduce maintenance needs, and increase safety in port operations.

9. Frequently Asked Questions

What is the primary function of hydraulic cylinders in maritime ports?

**Hydraulic cylinders** are used to convert hydraulic energy into mechanical force, enabling the movement of heavy cargo, cranes, and port machinery.

How do I know which hydraulic cylinder is suitable for my application?

Selecting the right hydraulic cylinder depends on the specific application, load requirements, and environmental conditions. Consulting with a hydraulic specialist can provide tailored recommendations.

What maintenance practices should be followed for hydraulic cylinders?

Regular inspections, fluid quality checks, seal replacements, and protective measures against environmental factors are essential for maintaining hydraulic cylinders.

Are there custom hydraulic cylinders available for unique applications?

Yes, many manufacturers offer custom hydraulic cylinders designed to meet specific requirements, including unique mounting configurations or materials.

What challenges do hydraulic cylinders face in maritime environments?

Challenges include corrosion from saltwater, operational stress from heavy loads, and the risk of fluid contamination, which can affect performance and longevity.

10. Conclusion

Hydraulic cylinders are an integral part of maritime port operations, providing the strength and precision needed for effective cargo handling and machinery operation. Understanding the different types of hydraulic cylinders and their applications helps in making informed decisions for efficient port management. By focusing on proper maintenance and embracing future technological advancements, ports can enhance their operational capabilities and ensure a safer working environment. As we look forward to innovations in hydraulic technology, the role of these essential components will remain crucial in the ever-evolving landscape of maritime logistics.

Previous Page

Previous Page

Questions?

We are here to help.