Understanding Hydraulic Cylinders in Mining Equipment: Essential Insights

2025-08-08

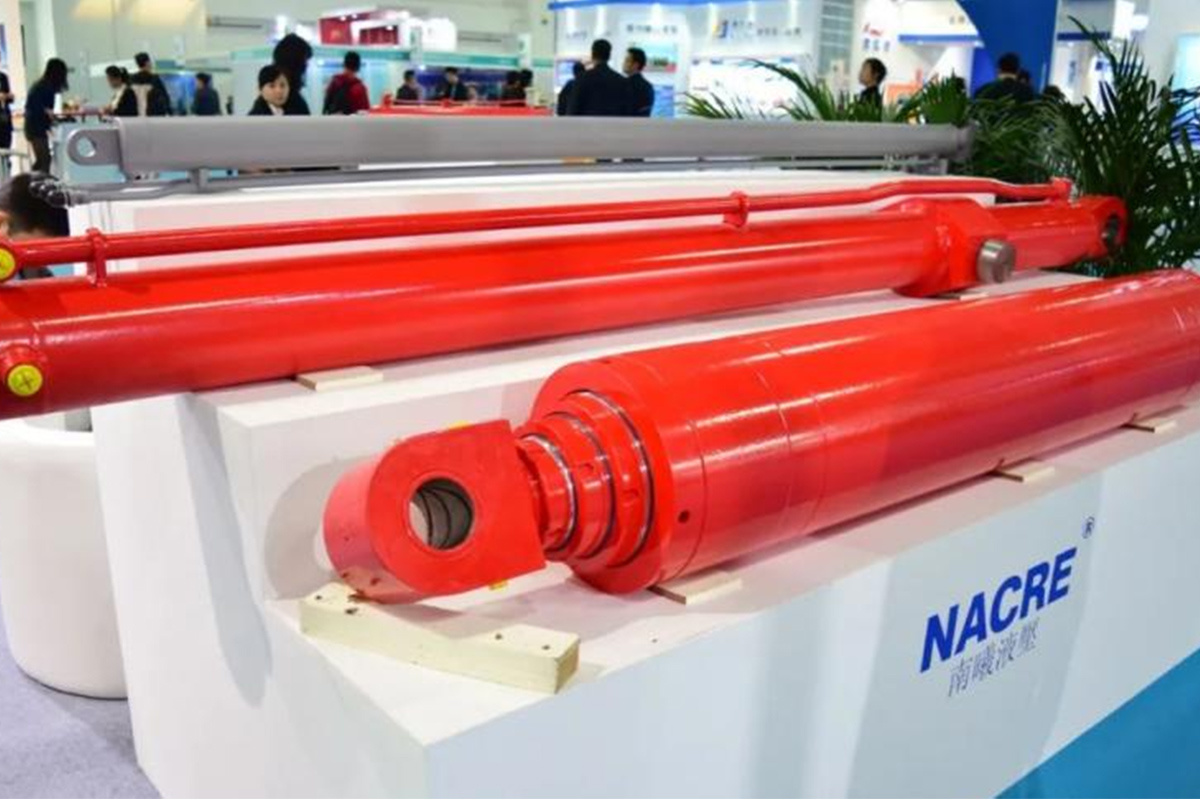

When it comes to industrial equipment, particularly in the mining industry, hydraulic cylinders are a cornerstone of operational efficiency and productivity. These cylinders are crucial components of hydraulic systems, converting hydraulic energy into mechanical force to perform a variety of tasks.

Hydraulic cylinders in mining equipment are designed to handle extreme conditions, including high pressure and heavy loads. They typically consist of a cylindrical barrel, a piston, and end caps that house the piston and hydraulic fluid. The hydraulic fluid, usually oil, is pumped into the cylinder, creating pressure that pushes the piston and generates movement. This movement can be linear or rotary, depending on the specific application.

One of the primary advantages of utilizing hydraulic cylinders in mining operations is their ability to provide a high amount of force with relatively small physical size. This makes them ideal for use in confined spaces or where weight is a concern. For instance, they are commonly used in excavators, loaders, and other heavy machinery to lift, push, and pull materials with precision and power.

In addition to their strength, hydraulic cylinders are known for their speed and efficiency. The controlled flow of hydraulic fluid allows for rapid actuation, which is essential in time-sensitive mining applications where productivity is key. Moreover, hydraulic systems can easily be automated or integrated with electronic controls, enhancing operational capabilities further.

Maintenance of hydraulic cylinders is critical to ensure longevity and reliability. Regular inspections for leaks, wear, or damage are essential. Proper lubrication and timely replacement of seals can prevent potential failures. Additionally, using the correct hydraulic fluid and ensuring the system is free of contaminants are vital practices that contribute to the efficient functioning of hydraulic cylinders in mining equipment.

Environmental considerations are also increasingly important in the mining industry. As companies seek to reduce their carbon footprint, advancements in hydraulic technology have led to the development of more energy-efficient systems. Innovations such as variable displacement pumps and regenerative circuits are examples of how the industry is evolving to meet these new challenges.

In conclusion, hydraulic cylinders are indispensable components in mining equipment, offering strength, speed, and reliability. Understanding their function, maintenance needs, and the latest advancements can significantly enhance operational efficiency in mining operations. By leveraging the technology of hydraulic systems, companies can optimize their equipment performance and contribute to more sustainable mining practices.

Hydraulic cylinders in mining equipment are designed to handle extreme conditions, including high pressure and heavy loads. They typically consist of a cylindrical barrel, a piston, and end caps that house the piston and hydraulic fluid. The hydraulic fluid, usually oil, is pumped into the cylinder, creating pressure that pushes the piston and generates movement. This movement can be linear or rotary, depending on the specific application.

One of the primary advantages of utilizing hydraulic cylinders in mining operations is their ability to provide a high amount of force with relatively small physical size. This makes them ideal for use in confined spaces or where weight is a concern. For instance, they are commonly used in excavators, loaders, and other heavy machinery to lift, push, and pull materials with precision and power.

In addition to their strength, hydraulic cylinders are known for their speed and efficiency. The controlled flow of hydraulic fluid allows for rapid actuation, which is essential in time-sensitive mining applications where productivity is key. Moreover, hydraulic systems can easily be automated or integrated with electronic controls, enhancing operational capabilities further.

Maintenance of hydraulic cylinders is critical to ensure longevity and reliability. Regular inspections for leaks, wear, or damage are essential. Proper lubrication and timely replacement of seals can prevent potential failures. Additionally, using the correct hydraulic fluid and ensuring the system is free of contaminants are vital practices that contribute to the efficient functioning of hydraulic cylinders in mining equipment.

Environmental considerations are also increasingly important in the mining industry. As companies seek to reduce their carbon footprint, advancements in hydraulic technology have led to the development of more energy-efficient systems. Innovations such as variable displacement pumps and regenerative circuits are examples of how the industry is evolving to meet these new challenges.

In conclusion, hydraulic cylinders are indispensable components in mining equipment, offering strength, speed, and reliability. Understanding their function, maintenance needs, and the latest advancements can significantly enhance operational efficiency in mining operations. By leveraging the technology of hydraulic systems, companies can optimize their equipment performance and contribute to more sustainable mining practices.

Previous Page

Previous Page

Questions?

We are here to help.