Understanding Excavator Cylinders: Key Components for Hydraulic Machinery

2025-08-14

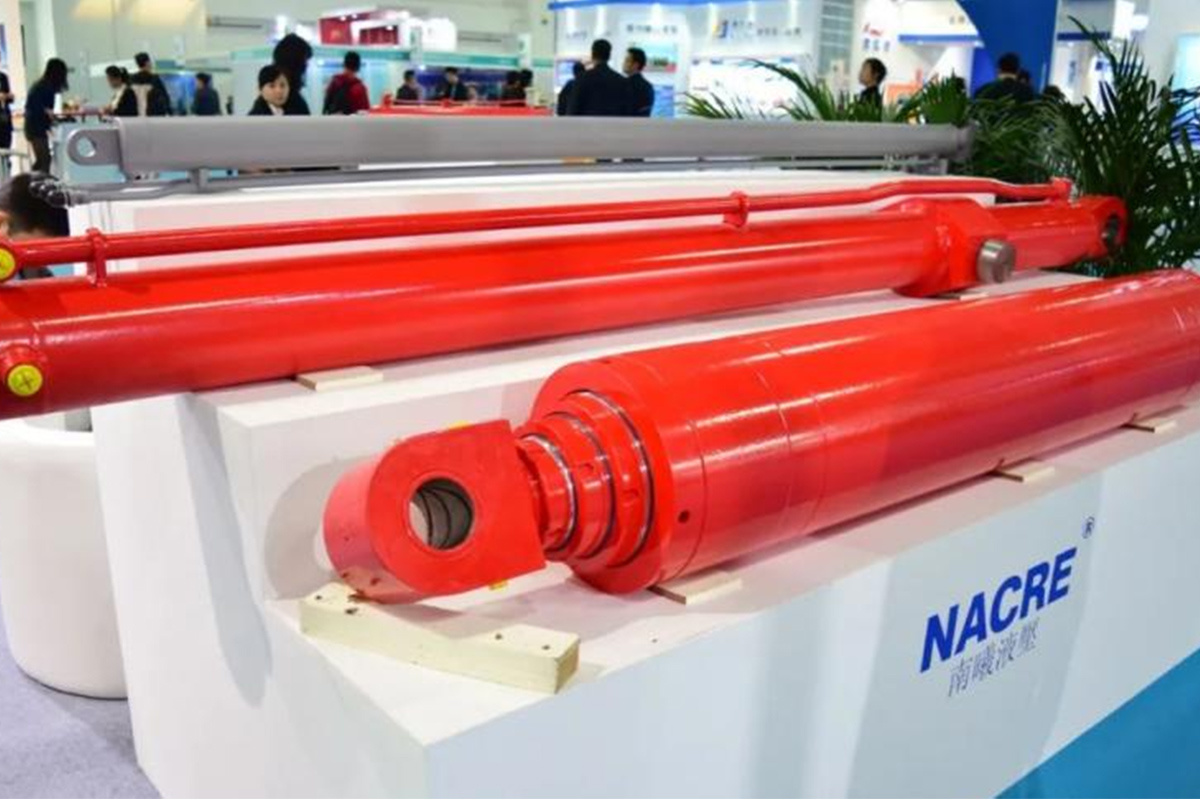

Excavator cylinders are critical components in hydraulic machinery, enabling various functions crucial for excavation and material handling. These hydraulic cylinders convert hydraulic energy into mechanical force, allowing excavators to perform tasks such as lifting, digging, and moving heavy loads. Understanding the mechanics and maintenance of excavator cylinders can significantly improve the efficiency and lifespan of hydraulic equipment.

A typical excavator cylinder consists of several key components, including the cylinder barrel, piston, rod, and seals. The cylinder barrel houses the hydraulic fluid, which is vital for generating the force needed for movement. As hydraulic fluid is pumped into the cylinder, it pushes the piston, which is connected to the excavator's arm or bucket. The movement of the piston translates into the desired motion, whether it’s extending or retracting the arm or rotating the bucket.

One important aspect to consider is the type of hydraulic fluid used in excavator cylinders. The fluid must meet specific viscosity and temperature requirements to ensure optimal performance. Using the wrong type of fluid can lead to inefficient operation and increased wear on the cylinder components. Regularly checking and replacing the hydraulic fluid is crucial for maintaining the functionality of the cylinder and the overall hydraulic system.

Additionally, the seals within the excavator cylinder play a vital role in preventing hydraulic fluid leaks. Over time, seals can wear out due to friction and exposure to harsh environmental conditions. Regular inspection of seals for signs of wear or damage is essential to avoid costly repairs and downtime. If leaks are detected, timely replacement of seals can prevent further damage to the cylinder and maintain efficient operation.

Maintenance is another critical factor in the longevity of excavator cylinders. Routine inspections should be performed to check for any signs of wear, including checking for leaks, corrosion, and physical damage. Keeping the cylinder clean and free from debris can also help prevent premature wear and ensure smooth operation.

In conclusion, excavator cylinders are fundamental to the operation of hydraulic machinery, converting hydraulic energy into the mechanical force required for various tasks. By understanding their components, ensuring the correct hydraulic fluid is used, maintaining seals, and implementing regular inspections, operators can enhance the efficiency and lifespan of these vital components. Proper maintenance and care of excavator cylinders will ultimately contribute to the overall performance of hydraulic equipment, leading to increased productivity and reduced operational costs.

A typical excavator cylinder consists of several key components, including the cylinder barrel, piston, rod, and seals. The cylinder barrel houses the hydraulic fluid, which is vital for generating the force needed for movement. As hydraulic fluid is pumped into the cylinder, it pushes the piston, which is connected to the excavator's arm or bucket. The movement of the piston translates into the desired motion, whether it’s extending or retracting the arm or rotating the bucket.

One important aspect to consider is the type of hydraulic fluid used in excavator cylinders. The fluid must meet specific viscosity and temperature requirements to ensure optimal performance. Using the wrong type of fluid can lead to inefficient operation and increased wear on the cylinder components. Regularly checking and replacing the hydraulic fluid is crucial for maintaining the functionality of the cylinder and the overall hydraulic system.

Additionally, the seals within the excavator cylinder play a vital role in preventing hydraulic fluid leaks. Over time, seals can wear out due to friction and exposure to harsh environmental conditions. Regular inspection of seals for signs of wear or damage is essential to avoid costly repairs and downtime. If leaks are detected, timely replacement of seals can prevent further damage to the cylinder and maintain efficient operation.

Maintenance is another critical factor in the longevity of excavator cylinders. Routine inspections should be performed to check for any signs of wear, including checking for leaks, corrosion, and physical damage. Keeping the cylinder clean and free from debris can also help prevent premature wear and ensure smooth operation.

In conclusion, excavator cylinders are fundamental to the operation of hydraulic machinery, converting hydraulic energy into the mechanical force required for various tasks. By understanding their components, ensuring the correct hydraulic fluid is used, maintaining seals, and implementing regular inspections, operators can enhance the efficiency and lifespan of these vital components. Proper maintenance and care of excavator cylinders will ultimately contribute to the overall performance of hydraulic equipment, leading to increased productivity and reduced operational costs.

Previous Page

Previous Page

Questions?

We are here to help.