Common Issues with Tractor Hydraulic Cylinders and How to Fix Them

2025-08-11

Common Issues with Tractor Hydraulic Cylinders and How to Fix Them

Table of Contents

- Introduction to Tractor Hydraulic Cylinders

- Understanding Hydraulic Cylinders in Tractors

- Common Issues with Tractor Hydraulic Cylinders

- Hydraulic Fluid Leaks

- Slow Response or No Movement

- Overheating of Hydraulic Cylinders

- Pitting and Wear on Cylinder Rods

- Contaminated Hydraulic Fluid

- Diagnosing Issues with Hydraulic Cylinders

- Repairing Hydraulic Cylinders: Step-by-Step Guide

- Repairing Hydraulic Leaks

- Fixing Slow Response Issues

- Addressing Overheating Problems

- Restoring Pitted Cylinder Rods

- Cleaning Contaminated Hydraulic Fluid

- Preventive Maintenance for Hydraulic Cylinders

- Conclusion

- FAQs about Tractor Hydraulic Cylinders

Introduction to Tractor Hydraulic Cylinders

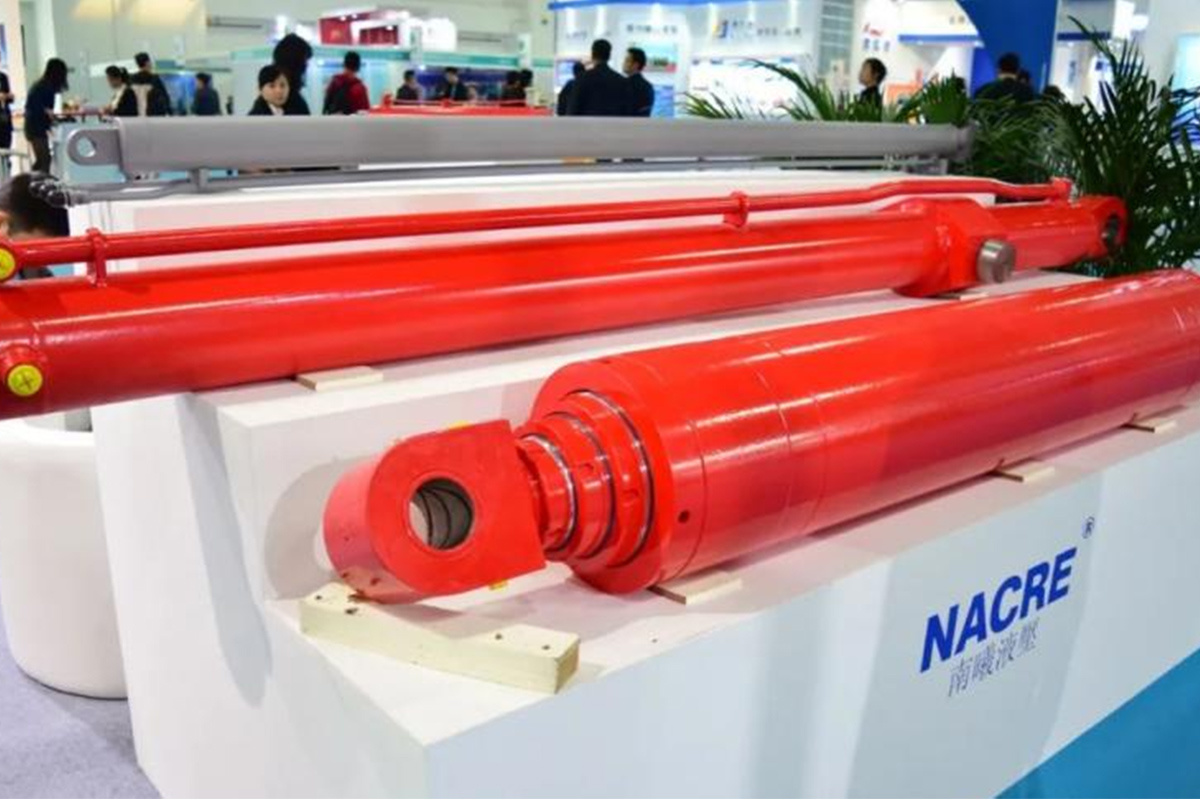

In the world of agricultural machinery, **tractor hydraulic cylinders** play a pivotal role in the functionality and efficiency of various implements. These components are responsible for converting hydraulic pressure into mechanical force, allowing tractors to perform a host of tasks, from lifting heavy loads to steering. However, just like any other machinery, hydraulic cylinders can encounter problems that hinder their performance.

Understanding these common issues, their causes, and solutions is essential for any tractor operator or owner. This detailed guide will delve into the most prevalent problems associated with tractor hydraulic cylinders and provide effective ways to fix them.

Understanding Hydraulic Cylinders in Tractors

Hydraulic cylinders consist of a cylindrical barrel, a piston, and rod, and they operate based on **Pascal’s principle**, which states that pressure applied to a confined fluid is transmitted undiminished in all directions. In tractors, hydraulic cylinders are essential for controlling the lifting and lowering of implements like plows, seeders, and loaders.

When hydraulic fluid is pumped into the cylinder, it exerts pressure on the piston, causing it to move. This movement is then converted into mechanical power that drives the tractor's actions. The efficiency of hydraulic cylinders is paramount, and any malfunction can lead to significant downtime and loss of productivity.

Common Issues with Tractor Hydraulic Cylinders

Despite their crucial role, hydraulic cylinders can face several common issues. Recognizing these problems early can save time and money, ensuring your tractor remains operational.

Hydraulic Fluid Leaks

**Hydraulic fluid leaks** are perhaps the most common issue encountered with tractor hydraulic cylinders. Leaks can occur due to worn seals, damaged fittings, or corroded tubing. Not only do leaks lead to a loss of hydraulic pressure, but they can also pose safety hazards.

**Signs of hydraulic fluid leaks** include visible fluid around the cylinder, diminished lifting capability, and an increased need for fluid top-ups. Identifying the source of the leak is critical for effective repair.

Slow Response or No Movement

Another prevalent issue is a **slow response** from the hydraulic system. When hydraulic cylinders do not respond promptly, it can stall operations and drastically affect productivity. Causes for slow movement can include low hydraulic fluid levels, air trapped in the system, or malfunctioning valves.

**Indicators of slow response** include sluggish lifting or lowering of implements and inconsistent movements. Diagnosing the underlying cause is essential for restoring functionality.

Overheating of Hydraulic Cylinders

**Overheating** can severely damage hydraulic cylinders and lead to catastrophic failure. High temperatures can result from excessive workload, low fluid levels, or contaminated fluid. An overheated hydraulic system can lead to seal failure and fluid breakdown.

**Symptoms of overheating** include abnormal fluid temperatures and visible signs of wear on cylinder components. Regular monitoring of temperature and proper fluid maintenance can help prevent overheating.

Pitting and Wear on Cylinder Rods

**Pitting** is a degradation of the cylinder rod surface, often caused by contamination in the hydraulic fluid or improper sealing. This wear can lead to significant performance issues and further damage to the hydraulic cylinder.

**Signs of pitting** include visible corrosion on the rod and reduced hydraulic pressure. Addressing pitting promptly is crucial to maintaining the integrity of the hydraulic system.

Contaminated Hydraulic Fluid

Hydraulic fluid contamination can result from dirt, debris, or water entering the system, leading to considerable issues. Contaminated fluid can damage seals, increase wear on components, and compromise overall hydraulic performance.

**Indicators of contaminated fluid** include discoloration, unusual odors, and the presence of particulates. Regular fluid checks and changes are vital for preventing contamination issues.

Diagnosing Issues with Hydraulic Cylinders

Diagnosing issues with hydraulic cylinders requires a systematic approach. Start by visually inspecting the cylinder for signs of leaks or pitting. Next, check the hydraulic fluid level and quality. If the fluid appears contaminated or low, it may be necessary to replace it.

**Using diagnostic tools**, such as pressure gauges and flow meters, can provide further insight into the functionality of the hydraulic system. Observing the response time and performance under various loads can also help identify specific issues.

Repairing Hydraulic Cylinders: Step-by-Step Guide

Once issues are diagnosed, the next step is to address them through effective repairs. Here’s a breakdown of how to tackle common problems with hydraulic cylinders.

Repairing Hydraulic Leaks

To repair hydraulic fluid leaks, start by identifying the leak source. If the issue lies with seals, it may be necessary to replace them. For damaged fittings, tightening or replacing them can often resolve the problem.

After repairs, refill the hydraulic fluid and monitor for any further signs of leaks. It's crucial to ensure that all components are sealed properly to prevent future issues.

Fixing Slow Response Issues

To address slow response problems, first, check the hydraulic fluid levels and top up as needed. Bleeding the hydraulic system to remove trapped air is often necessary. Ensure that all valves are functioning correctly and free from obstructions.

Performing these checks can significantly improve the response time of hydraulic cylinders.

Addressing Overheating Problems

To combat overheating, start by checking the hydraulic fluid level and topping up if needed. If overheating persists, consider reducing the workload or assessing whether the hydraulic system is adequately sized for its tasks.

Regular maintenance, including changing the hydraulic fluid, can help prevent overheating issues in the future.

Restoring Pitted Cylinder Rods

Restoring pitted cylinder rods requires professional repairs, such as re-chroming or using specialized coatings to repair the surface. In some cases, replacing the rod may be necessary to ensure optimal function.

Preventative measures, such as using high-quality seals and maintaining clean hydraulic fluid, can help reduce the likelihood of pitting.

Cleaning Contaminated Hydraulic Fluid

When hydraulic fluid contamination is detected, immediate action should be taken. Start by draining the contaminated fluid and replacing it with fresh, clean hydraulic fluid.

Incorporating filtration systems can help prevent future contamination and extend the life of your hydraulic components.

Preventive Maintenance for Hydraulic Cylinders

Implementing a **preventive maintenance** schedule is crucial for the longevity of your tractor's hydraulic cylinders. Regular inspections, fluid changes, and checking for leaks can significantly reduce the risk of unexpected failures.

1. **Regularly Inspect Hydraulic Cylinders**: Check for signs of wear, leaks, and pitting.

2. **Monitor Hydraulic Fluid Levels**: Ensure fluid levels are always sufficient and clean.

3. **Change Hydraulic Fluid**: Follow manufacturer recommendations for fluid changes to prevent contamination.

4. **Use Quality Seals**: Invest in high-quality seals to minimize leaks and wear.

5. **Train Operators**: Ensure that tractor operators are trained to recognize signs of hydraulic system issues.

By practicing these preventive measures, operators can extend the lifespan of hydraulic cylinders and maintain optimal performance.

Conclusion

Understanding the common issues that can arise with tractor hydraulic cylinders is essential for maintaining operational efficiency. By recognizing symptoms early and implementing effective repair and maintenance strategies, tractor owners can prevent downtime and costly repairs.

Keeping hydraulic systems in peak condition not only enhances performance but also ensures the safety and productivity of agricultural operations. Regular inspections, prompt repairs, and a commitment to preventive maintenance will go a long way in safeguarding your hydraulic system.

FAQs about Tractor Hydraulic Cylinders

1. What are the most common causes of hydraulic cylinder leaks?

Common causes include worn seals, damaged fittings, and corrosion on tubing.

2. How can I tell if my hydraulic fluid is contaminated?

Signs of contamination include discoloration, unusual odors, and the presence of particulates in the fluid.

3. What should I do if my hydraulic cylinder is overheating?

Check fluid levels, reduce workload, and ensure the system is sized correctly for its tasks to prevent overheating.

4. How often should hydraulic fluid be changed?

It is recommended to change hydraulic fluid based on the manufacturer’s guidelines—typically every 1,000 hours of operation or at least once a year.

5. Can I repair a pitted cylinder rod myself?

While minor repairs can be attempted, it is generally advised to seek professional help for restoring pitted cylinder rods to ensure proper function and safety.

By understanding the intricacies of tractor hydraulic cylinders and addressing common issues proactively, operators can ensure their machinery remains reliable and efficient throughout its service life.

Previous Page

Previous Page

Questions?

We are here to help.