Maximizing Productivity with Advanced Loader Hydraulic Cylinder Technology

2025-08-17

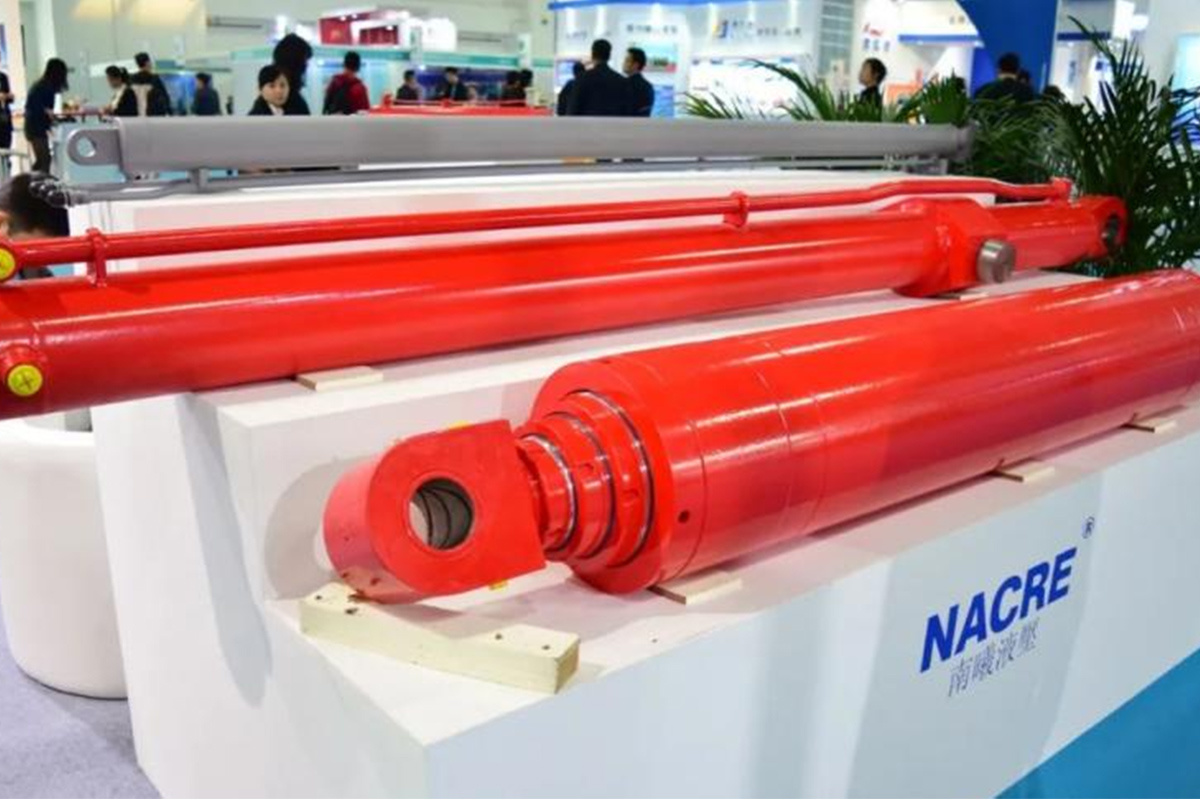

Maximizing Productivity with Advanced Loader Hydraulic Cylinder Technology

Introduction to Hydraulic Cylinder Technology

In the realm of industrial equipment and components, hydraulic systems play a pivotal role in enhancing operational efficiency. Advanced loader hydraulic cylinder technology has emerged as a game-changer, significantly impacting productivity across various sectors. Understanding the mechanics behind hydraulic cylinders and their applications can help businesses optimize performance and reduce downtime.

Understanding Hydraulic Cylinders: The Heart of Loader Systems

Hydraulic cylinders are pivotal components in loader systems, serving as the driving force behind lifting and moving heavy loads. They convert hydraulic energy into mechanical energy, allowing for precise control and powerful force application.

The Mechanics of Hydraulic Cylinders

At the core of a hydraulic cylinder lies its basic structure, which includes:

- **Cylinder Barrel**: The main body that houses the piston.

- **Piston**: The moving element that generates force.

- **Rod**: Connects the piston to the external load.

- **End Caps**: Seal the cylinder and allow for hydraulic fluid entry and exit.

When hydraulic fluid is pumped into the cylinder, it creates pressure that moves the piston. This movement can be linear or rotational, depending on the application, making hydraulic cylinders versatile for various tasks.

Key Components and Their Functions

1. **Hydraulic Fluid**: Acts as the medium for energy transfer.

2. **Seals**: Prevent leaks and maintain pressure.

3. **Ports**: Allow hydraulic fluid to enter and exit the cylinder.

4. **Mounting Accessories**: Ensure the cylinder is securely attached to the loader.

Benefits of Advanced Loader Hydraulic Cylinders

The integration of advanced technology in hydraulic cylinders offers numerous benefits that can dramatically enhance productivity.

Improved Efficiency and Performance

Advanced hydraulic cylinders are designed to operate at higher pressures, which translates to greater lifting capacity without increasing the size of the cylinder. This optimization leads to:

- **Faster Cycle Times**: Quicker operations result in increased throughput.

- **Lower Energy Consumption**: Enhanced efficiency means reduced energy costs.

Enhanced Durability and Reliability

Modern hydraulic cylinders are built with advanced materials and coatings that resist wear and corrosion. This results in:

- **Longer Lifespan**: Reduced maintenance needs and extended service intervals.

- **Increased Uptime**: Less down-time for repairs translates to higher productivity.

Innovations in Hydraulic Cylinder Technology

The hydraulic industry is continually evolving, with innovations that enhance the capabilities of loader hydraulic cylinders.

Smart Hydraulic Systems

Integrating digital technology allows for real-time monitoring and control of hydraulic systems. Smart sensors can provide:

- **Performance Data**: Inform operators when maintenance is needed.

- **Remote Monitoring**: Enable oversight of hydraulic performance from anywhere.

Eco-Friendly Hydraulic Fluids

With a growing emphasis on sustainability, eco-friendly hydraulic fluids are gaining popularity. These fluids provide:

- **Reduced Environmental Impact**: Less harmful to the environment if leaks occur.

- **Improved Efficiency**: Often formulated to enhance the performance of hydraulic systems.

Choosing the Right Hydraulic Cylinder for Your Loader

Selecting the appropriate hydraulic cylinder is critical for optimizing your loader's performance. Consider the following factors:

Load Capacity and Application

Understanding the specific tasks your loader will perform will guide you in selecting a hydraulic cylinder with the appropriate capacity. Consider:

- **Working Pressure**: Choose a cylinder that can handle the maximum pressure for your applications.

- **Stroke Length**: Ensure the stroke length meets the required lifting height.

Operating Environment

Assess the conditions in which the loader will operate. Factors like temperature extremes, exposure to corrosive substances, and physical space constraints can influence your choice.

Maintenance Tips for Hydraulic Cylinders

Proper maintenance is vital to ensuring the longevity and efficiency of hydraulic cylinders. We recommend several best practices:

Regular Inspections

Conduct frequent inspections to detect wear and leaks. Identifying issues early can prevent costly downtime.

Fluid Quality Checks

Regularly check the hydraulic fluid for contaminants and ensure it meets manufacturer specifications for optimal performance.

Case Studies: Successful Implementations of Advanced Hydraulic Technology

Examining real-world applications can provide actionable insights into maximizing productivity with advanced loader hydraulic cylinders.

Case Study 1: Construction Industry

A prominent construction company integrated advanced hydraulic cylinders into their earth-moving equipment, resulting in a 30% increase in efficiency. By utilizing smart sensors, they reduced operational downtime and optimized their workflow.

Case Study 2: Agricultural Sector

Farmers who adopted eco-friendly hydraulic systems reported significant savings in operational costs due to lower energy consumption and improved equipment performance.

Future Trends in Loader Hydraulic Cylinder Technology

As technology continues to evolve, so will the capabilities of hydraulic systems. Future trends may include:

Automation and AI Integration

The integration of artificial intelligence can lead to more sophisticated hydraulic systems capable of self-diagnosis and autonomous operation.

Advanced Materials and Manufacturing Techniques

Innovations in materials science may yield even more durable and lightweight hydraulic cylinders, further increasing efficiency.

FAQs about Advanced Loader Hydraulic Cylinder Technology

1. What should I consider when selecting a hydraulic cylinder for my loader?

Consider load capacity, stroke length, operating environment, and maintenance requirements.

2. How often should I perform maintenance on hydraulic cylinders?

Regular inspections should be conducted at least quarterly, with maintenance performed as necessary based on usage.

3. What are the signs of hydraulic cylinder failure?

Common signs include fluid leaks, unusual noises, and reduced lifting capacity.

4. Can I upgrade my existing hydraulic cylinders?

In many cases, upgrades are possible through retrofitting with new technology or replacement with more advanced models.

5. What are the benefits of eco-friendly hydraulic fluids?

Eco-friendly fluids reduce environmental impact, lower toxicity risks, and can enhance the performance of hydraulic systems.

Conclusion

Maximizing productivity in industrial operations hinges on the adoption of advanced loader hydraulic cylinder technology. By understanding the mechanics, benefits, innovations, and maintenance practices associated with hydraulic cylinders, businesses can significantly enhance their performance. Embracing these advancements not only improves efficiency but also positions companies for future growth in an increasingly competitive landscape. Investing in the right technology today will pay dividends in productivity and efficiency tomorrow.

Previous Page

Previous Page

Questions?

We are here to help.