Understanding Tractor Loader Cylinders: Key Components for Enhanced Performance

2025-08-20

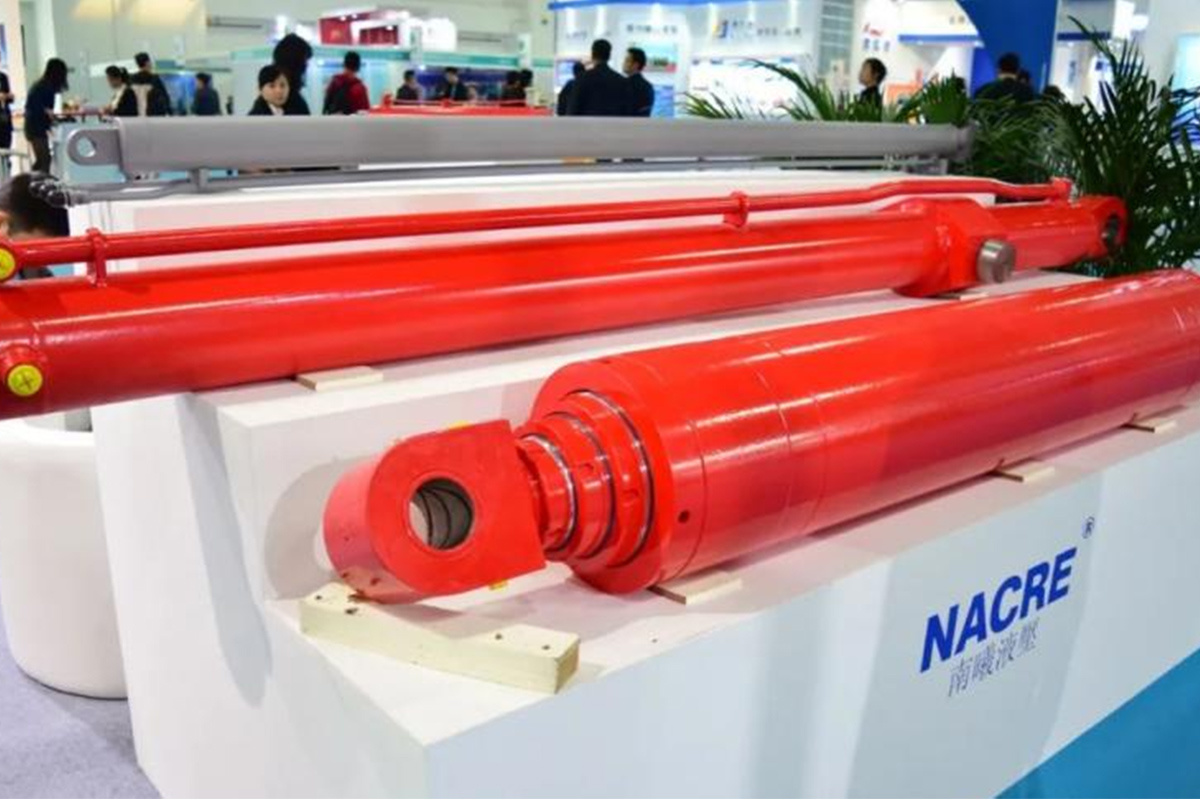

Tractor loader cylinders are vital components within hydraulic systems that power various machinery, particularly in construction and agricultural applications. These cylinders convert hydraulic energy into mechanical force, enabling the loader's arms to lift, lower, and tilt effectively. Understanding the intricacies of tractor loader cylinders is crucial for professionals looking to enhance the performance and longevity of their equipment.

At their core, tractor loader cylinders consist of a cylindrical barrel, piston, seals, and end caps. When hydraulic fluid is pumped into the cylinder, the pressure pushes the piston outward, resulting in linear motion. This motion is what allows operators to perform tasks such as lifting heavy loads or digging into the ground. The design and material selection of these cylinders are critical, as they must withstand significant pressure and harsh environmental conditions.

There are typically two main types of tractor loader cylinders: single-acting and double-acting. Single-acting cylinders use hydraulic fluid to move the piston in one direction, with a spring or gravity returning it to the starting position. In contrast, double-acting cylinders allow fluid to enter on both sides of the piston, enabling movement in both directions. This functionality is often preferred in applications requiring precise control and speed.

Proper maintenance of tractor loader cylinders is essential for ensuring optimal performance and preventing costly downtime. Regular inspections for leaks, wear, and tear can help detect issues early. It's also important to maintain the hydraulic fluid at the appropriate levels and replace it as needed to prevent contamination that could damage the cylinder seals. Additionally, operators should be aware of the load limits and avoid exceeding them, as this can lead to cylinder failure.

In conclusion, tractor loader cylinders are integral to the effective operation of hydraulic equipment. By understanding their function, types, and maintenance needs, professionals in the industrial machinery sector can ensure their equipment runs smoothly and efficiently. Investing time in the care of these cylinders not only enhances performance but also extends the life of the machinery, ultimately contributing to improved productivity on the job site.

At their core, tractor loader cylinders consist of a cylindrical barrel, piston, seals, and end caps. When hydraulic fluid is pumped into the cylinder, the pressure pushes the piston outward, resulting in linear motion. This motion is what allows operators to perform tasks such as lifting heavy loads or digging into the ground. The design and material selection of these cylinders are critical, as they must withstand significant pressure and harsh environmental conditions.

There are typically two main types of tractor loader cylinders: single-acting and double-acting. Single-acting cylinders use hydraulic fluid to move the piston in one direction, with a spring or gravity returning it to the starting position. In contrast, double-acting cylinders allow fluid to enter on both sides of the piston, enabling movement in both directions. This functionality is often preferred in applications requiring precise control and speed.

Proper maintenance of tractor loader cylinders is essential for ensuring optimal performance and preventing costly downtime. Regular inspections for leaks, wear, and tear can help detect issues early. It's also important to maintain the hydraulic fluid at the appropriate levels and replace it as needed to prevent contamination that could damage the cylinder seals. Additionally, operators should be aware of the load limits and avoid exceeding them, as this can lead to cylinder failure.

In conclusion, tractor loader cylinders are integral to the effective operation of hydraulic equipment. By understanding their function, types, and maintenance needs, professionals in the industrial machinery sector can ensure their equipment runs smoothly and efficiently. Investing time in the care of these cylinders not only enhances performance but also extends the life of the machinery, ultimately contributing to improved productivity on the job site.

Questions?

We are here to help.