Essential Maintenance Tips for Extending the Life of Your Tie Rod Cylinders

2025-08-23

Essential Maintenance Tips for Extending the Life of Your Tie Rod Cylinders

Table of Contents

- 1. Introduction to Tie Rod Cylinders

- 2. Understanding the Importance of Maintenance

- 3. Common Issues Faced by Tie Rod Cylinders

- 4. Maintenance Tips for Optimal Performance

- 4.1 Regular Inspections

- 4.2 Cleaning Procedures for Tie Rod Cylinders

- 4.3 Proper Lubrication Techniques

- 4.4 Inspecting Seals and Gaskets

- 4.5 Troubleshooting Common Problems

- 5. Preventive Maintenance Strategies

- 6. When to Call the Professionals

- 7. Conclusion

- 8. Frequently Asked Questions

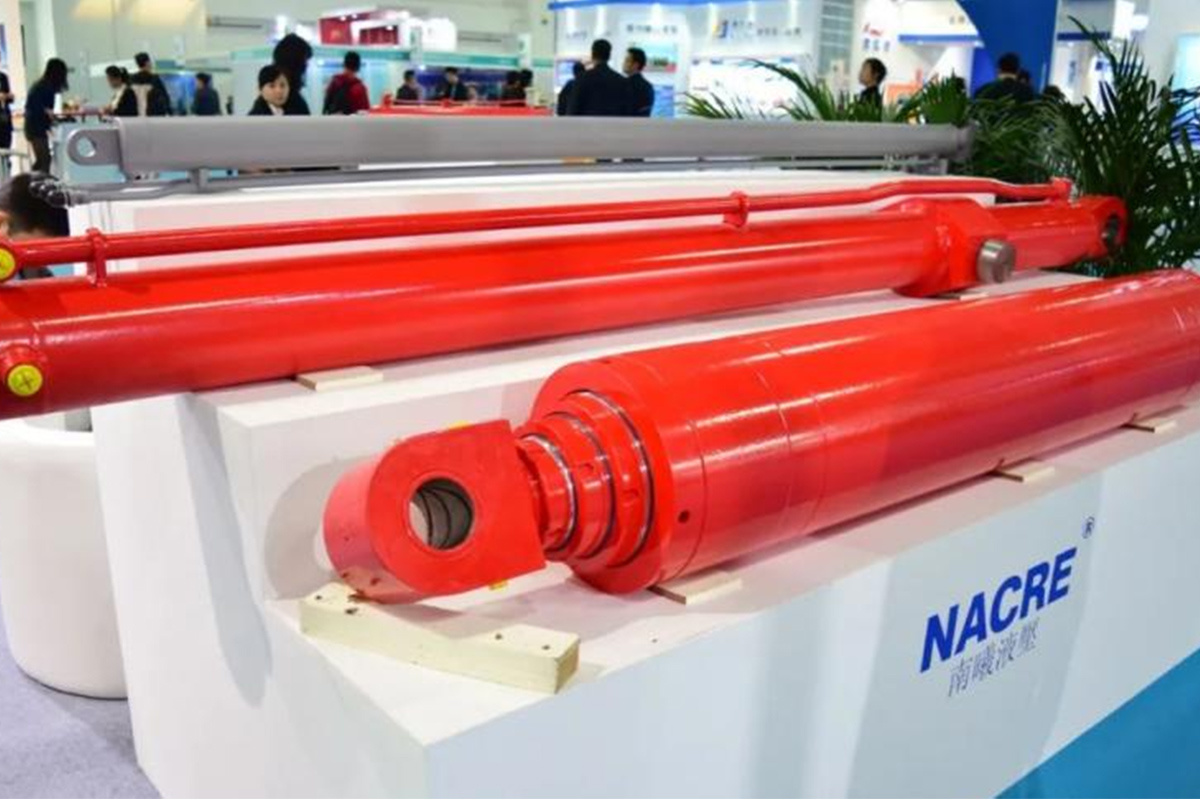

1. Introduction to Tie Rod Cylinders

Tie rod cylinders play a critical role in hydraulic systems, widely utilized in various industrial applications such as construction, manufacturing, and agriculture. These cylinders are favored for their reliability and robust design, making them suitable for high-pressure environments. However, to ensure optimal performance and longevity, regular maintenance is vital. This article offers detailed maintenance tips specifically tailored for tie rod cylinders, focusing on practices that can significantly extend their life.

2. Understanding the Importance of Maintenance

Regular maintenance of tie rod cylinders is essential for several reasons:

- **Performance Efficiency**: Well-maintained cylinders operate at peak efficiency, ensuring that hydraulic systems deliver the expected functionality.

- **Cost Savings**: Preventative maintenance reduces the risk of expensive repairs or replacements caused by neglect.

- **Safety**: Malfunctioning hydraulic systems can pose serious safety hazards in industrial settings. Regular checks help mitigate these risks.

By understanding the importance of maintenance, operators can proactively address potential issues before they escalate.

3. Common Issues Faced by Tie Rod Cylinders

Tie rod cylinders, while robust, are not immune to problems. Common issues include:

- **Fluid Leaks**: Often caused by worn seals or excessive pressure, fluid leaks can lead to significant performance drops.

- **Rod Misalignment**: Misaligned rods can cause uneven wear and tear, leading to premature failure.

- **Corrosion**: Exposure to harsh environments can lead to corrosion, impacting both functionality and lifespan.

- **Overheating**: Excessive heat can damage seals and reduce fluid efficacy, leading to further complications.

Being aware of these common issues allows for targeted maintenance efforts.

4. Maintenance Tips for Optimal Performance

To keep your tie rod cylinders in excellent condition, consider implementing the following maintenance tips:

4.1 Regular Inspections

Conducting regular inspections is the first step in a comprehensive maintenance strategy. Look for the following signs:

- **Leakage**: Check around the seals and connection points for any signs of fluid leakage.

- **Physical Damage**: Inspect the cylinder body for any dents, scratches, or signs of wear that may affect operation.

- **Rod Condition**: Ensure that the rod is free from scratches and bends, as these can lead to more severe problems.

Document your findings and schedule repairs as necessary.

4.2 Cleaning Procedures for Tie Rod Cylinders

Cleaning your tie rod cylinders regularly helps remove dirt and debris that can cause wear. Follow these steps:

- **Use a Soft Cloth**: Wipe the exterior with a soft cloth to prevent scratching.

- **Avoid Harsh Chemicals**: Use mild detergent solutions to clean the surfaces, avoiding harsh chemicals that can damage seals.

- **Inspect While Cleaning**: Take this opportunity to inspect the cylinder for any signs of damage or wear.

A clean cylinder is not only more efficient but also easier to maintain.

4.3 Proper Lubrication Techniques

Lubrication is crucial for the smooth operation of tie rod cylinders. Ensure you:

- **Use the Right Lubricant**: Always use the manufacturer-recommended lubricant to avoid compatibility issues.

- **Apply Sparingly**: Too much grease can attract dirt, leading to blockages and increased wear.

- **Schedule Lubrication**: Create a lubrication schedule based on operational hours or usage to ensure consistent maintenance.

Proper lubrication reduces friction and wear, extending the life of the components.

4.4 Inspecting Seals and Gaskets

The integrity of seals and gaskets is essential for leak prevention. Regular inspections should include:

- **Visual Checks**: Look for cracks or deformities in seals and gaskets.

- **Replace When Necessary**: If any wear is detected, replace these components immediately to prevent fluid loss.

- **Check for Signs of Wear**: Pay attention to any fluid accumulation around seals, indicating potential wear.

Maintaining the integrity of seals and gaskets is critical for optimal cylinder performance.

4.5 Troubleshooting Common Problems

Understanding how to troubleshoot common problems can save time and resources:

- **Fluid Leaks**: Identify the source of the leak and replace seals or tighten fittings as needed.

- **Poor Performance**: Evaluate the hydraulic fluid levels and check for contaminants.

- **Overheating**: Ensure proper cooling measures are in place, such as adequate airflow and coolant levels.

Being proactive in troubleshooting can prevent minor issues from becoming major repairs.

5. Preventive Maintenance Strategies

Preventive maintenance goes beyond routine checks and involves strategic planning:

- **Develop a Maintenance Schedule**: Create a detailed schedule that outlines when inspections, cleanings, and lubrications should occur.

- **Training for Operators**: Ensure that all operators are trained in recognizing signs of wear and proper maintenance procedures.

- **Documentation**: Keep records of all maintenance activities, which can help identify patterns and inform future maintenance decisions.

Implementing these strategies ensures consistent upkeep and avoids unexpected breakdowns.

6. When to Call the Professionals

Even with diligent maintenance, there may be times when professional intervention is necessary:

- **Complex Repairs**: If a significant issue arises, such as severe internal damage, it’s best to consult a professional.

- **Lack of Expertise**: If the maintenance tasks exceed the skill level of your team, don’t hesitate to call for help.

- **Regular Audits**: Consider scheduling professional audits to review your maintenance practices and ensure compliance with industry standards.

Knowing when to seek professional assistance can prevent costly downtime and ensure safe operations.

7. Conclusion

In conclusion, extending the life of your tie rod cylinders hinges on a commitment to maintenance and proactive care. By implementing regular inspections, proper cleaning, and strategic lubrication, you can minimize the risk of failures and enhance performance. Additionally, understanding the common issues that affect tie rod cylinders, along with preventive strategies, can save your organization time and resources. Remember that while some problems may be manageable in-house, knowing when to consult professionals is crucial for optimal safety and efficiency.

8. Frequently Asked Questions

What are tie rod cylinders used for?

Tie rod cylinders are hydraulic components used to convert hydraulic pressure into linear motion, commonly found in machinery such as excavators and forklifts.

How often should I inspect my tie rod cylinders?

It is recommended to inspect tie rod cylinders at least once a month, or more frequently based on usage and operational conditions.

What should I do if I notice a leak in my tie rod cylinder?

Identify the source of the leak, check seals and fittings for wear, and replace any damaged components immediately to prevent further fluid loss.

Can I perform maintenance on tie rod cylinders myself?

Yes, basic maintenance such as cleaning, lubrication, and visual inspections can be performed by trained personnel. However, complex repairs should be handled by professionals.

What are the signs that my tie rod cylinder needs replacement?

Signs include persistent leaks, visible physical damage, decreased performance, or abnormal noises during operation. If multiple issues arise simultaneously, replacement may be necessary.

By adhering to these maintenance tips and guidelines, we can ensure that our tie rod cylinders remain in optimal condition, ultimately extending their lifespan and enhancing our hydraulic systems' efficiency.

Previous Page

Previous Page

Questions?

We are here to help.