Understanding Tower Crane Hydraulic Cylinders: Key Insights for Efficient Operation

2025-09-01

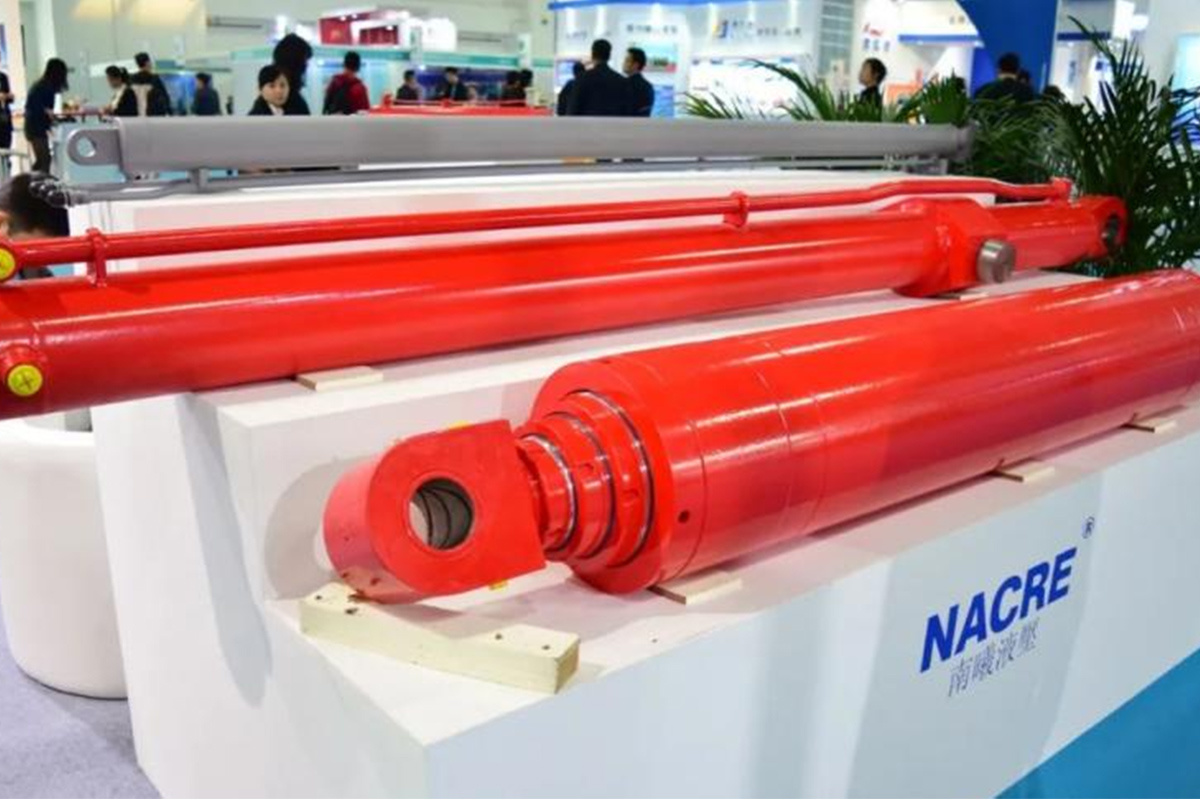

Tower crane hydraulic cylinders are vital components that play a crucial role in the operation of tower cranes, which are commonly used in construction and heavy lifting applications. These hydraulic cylinders are responsible for generating the force necessary to move and lift heavy loads vertically and horizontally. Their design and functionality directly impact the efficiency and safety of crane operations.

At the core of a tower crane hydraulic cylinder is the principle of hydraulics, which utilizes pressurized fluid to create mechanical motion. When hydraulic fluid is pumped into the cylinder, it pushes the piston, which in turn moves the crane's boom or other lifting mechanisms. This system allows for precise control over lifting operations, enabling operators to adjust the height and position of loads with great accuracy. Understanding this mechanism is crucial for anyone involved in the operation or maintenance of tower cranes.

Regular maintenance of hydraulic cylinders is essential to ensure their longevity and reliable performance. Operators should monitor the hydraulic fluid levels and check for any leaks, as a drop in fluid can lead to reduced lifting capacity and potentially dangerous situations. Additionally, the seals within the cylinders should be inspected regularly for wear and tear, as damaged seals can lead to fluid loss and compromised functionality. Keeping the hydraulic system clean and free from contaminants is also paramount; dirt and debris can cause significant damage over time.

To further enhance the performance of tower crane hydraulic cylinders, operators should be familiar with best practices in operation. For instance, understanding load limits and avoiding sudden movements can prevent unnecessary strain on hydraulic components. Additionally, training operators on the proper use of controls can minimize wear and extend the life of the hydraulic system.

In conclusion, the importance of tower crane hydraulic cylinders cannot be overstated in the realm of construction and industrial equipment. Their ability to provide powerful lifting capabilities while ensuring precision control makes them a critical aspect of tower crane functionality. By prioritizing regular maintenance, adhering to best practices, and understanding the underlying hydraulic principles, operators can enhance the safety and efficiency of their crane operations, ultimately contributing to successful project completions.

At the core of a tower crane hydraulic cylinder is the principle of hydraulics, which utilizes pressurized fluid to create mechanical motion. When hydraulic fluid is pumped into the cylinder, it pushes the piston, which in turn moves the crane's boom or other lifting mechanisms. This system allows for precise control over lifting operations, enabling operators to adjust the height and position of loads with great accuracy. Understanding this mechanism is crucial for anyone involved in the operation or maintenance of tower cranes.

Regular maintenance of hydraulic cylinders is essential to ensure their longevity and reliable performance. Operators should monitor the hydraulic fluid levels and check for any leaks, as a drop in fluid can lead to reduced lifting capacity and potentially dangerous situations. Additionally, the seals within the cylinders should be inspected regularly for wear and tear, as damaged seals can lead to fluid loss and compromised functionality. Keeping the hydraulic system clean and free from contaminants is also paramount; dirt and debris can cause significant damage over time.

To further enhance the performance of tower crane hydraulic cylinders, operators should be familiar with best practices in operation. For instance, understanding load limits and avoiding sudden movements can prevent unnecessary strain on hydraulic components. Additionally, training operators on the proper use of controls can minimize wear and extend the life of the hydraulic system.

In conclusion, the importance of tower crane hydraulic cylinders cannot be overstated in the realm of construction and industrial equipment. Their ability to provide powerful lifting capabilities while ensuring precision control makes them a critical aspect of tower crane functionality. By prioritizing regular maintenance, adhering to best practices, and understanding the underlying hydraulic principles, operators can enhance the safety and efficiency of their crane operations, ultimately contributing to successful project completions.

Questions?

We are here to help.