Innovative Hydraulic Cylinder Technologies for Pile Machinery: Revolutionizing Construction Efficiency

2025-09-04

Innovative Hydraulic Cylinder Technologies for Pile Machinery

Table of Contents

1. Introduction to Hydraulic Cylinders in Pile Machinery

2. Importance of Hydraulic Cylinders in Construction

3. Recent Developments in Hydraulic Cylinder Technologies

3.1 Smart Hydraulic Cylinders

3.2 Eco-Friendly Hydraulic Solutions

4. Key Features of Modern Hydraulic Cylinders

4.1 Enhanced Durability and Reliability

4.2 Improved Energy Efficiency

5. Applications of Advanced Hydraulic Cylinders in Pile Machinery

5.1 Deep Foundation Drilling

5.2 Sheet Pile Installation

6. Challenges and Solutions in Hydraulic Cylinder Technology

7. Future Trends in Hydraulic Cylinder Design

8. Conclusion

9. Frequently Asked Questions (FAQs)

1. Introduction to Hydraulic Cylinders in Pile Machinery

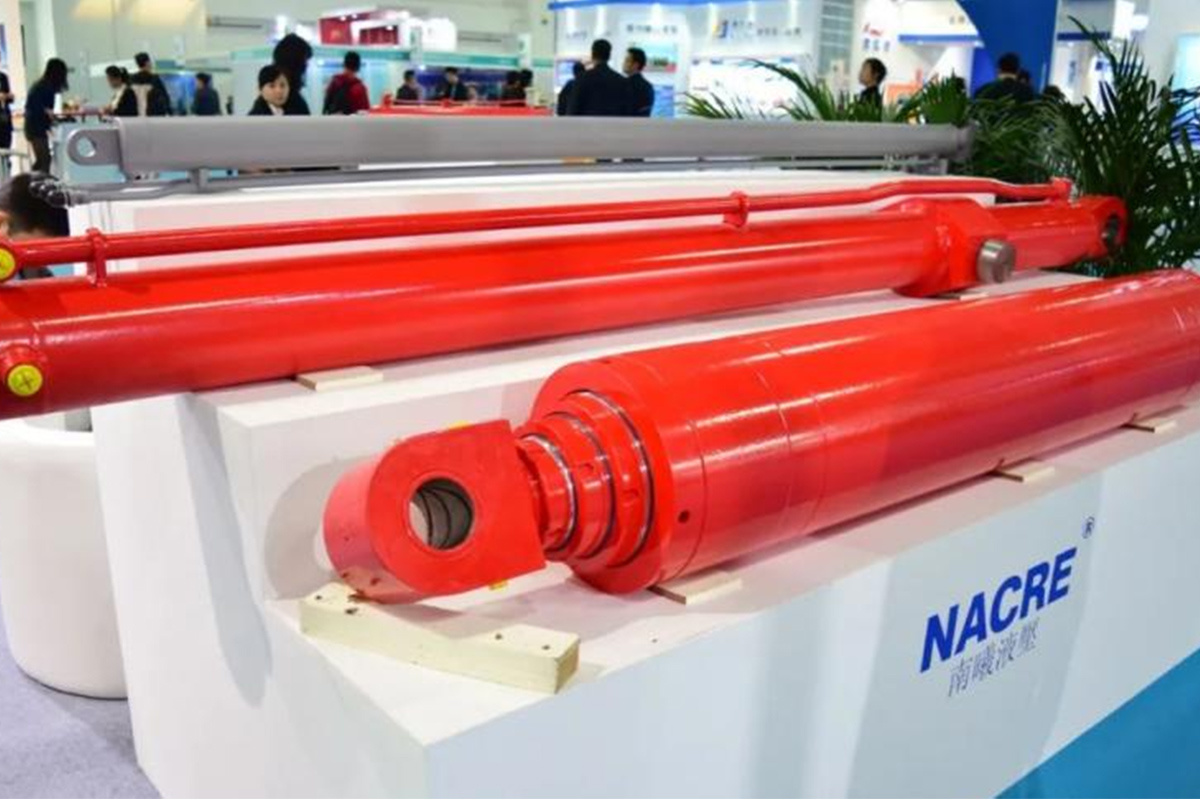

Hydraulic cylinders serve as the backbone of pile machinery in modern construction. Their primary function is to convert hydraulic energy into mechanical power, facilitating the lifting and lowering of heavy equipment and materials. As the construction industry evolves, so do the challenges and demands placed on hydraulic systems, making innovative technologies crucial for achieving higher efficiency and reliability.

2. Importance of Hydraulic Cylinders in Construction

In pile machinery, hydraulic cylinders are essential for tasks such as driving piles into the ground, lifting heavy loads, and providing the necessary force for various applications. Their ability to generate high levels of force in compact spaces makes them invaluable for construction sites, where space and precision are often at a premium. Furthermore, advancements in hydraulic technologies are enabling construction companies to meet stringent environmental regulations while improving safety and performance.

3. Recent Developments in Hydraulic Cylinder Technologies

The landscape of hydraulic cylinder technologies has changed dramatically in recent years, driven by the need for higher efficiency, better performance, and reduced environmental impact.

3.1 Smart Hydraulic Cylinders

The integration of smart technology into hydraulic cylinders is one of the most significant developments. Smart hydraulic cylinders come equipped with sensors that monitor performance metrics such as pressure, temperature, and position. This data can be transmitted in real-time to operators or control systems, allowing for proactive maintenance and improved operational efficiency.

3.2 Eco-Friendly Hydraulic Solutions

The push for sustainability has led to the development of eco-friendly hydraulic solutions. These systems utilize biodegradable hydraulic fluids and advanced materials designed to reduce environmental impact while maintaining performance. Such innovations not only meet regulatory requirements but also contribute to the overall sustainability goals of construction firms.

4. Key Features of Modern Hydraulic Cylinders

Modern hydraulic cylinders boast several features that enhance their performance and adaptability for various applications.

4.1 Enhanced Durability and Reliability

Today's hydraulic cylinders are designed to withstand harsh operating conditions. Advanced materials, surface treatments, and sealing technologies contribute to improved durability, reducing maintenance costs and extending the lifespan of the equipment.

4.2 Improved Energy Efficiency

Many hydraulic cylinders now incorporate energy-efficient designs that minimize power consumption. This not only reduces operational costs but also lowers the overall carbon footprint of construction projects.

5. Applications of Advanced Hydraulic Cylinders in Pile Machinery

The versatility of hydraulic cylinders allows them to be used in a wide range of pile machinery applications.

5.1 Deep Foundation Drilling

In deep foundation drilling, hydraulic cylinders provide the necessary force to drive drill bits into challenging soil conditions. Advanced hydraulic technologies ensure consistent performance, even in difficult environments, improving drilling accuracy and speed.

5.2 Sheet Pile Installation

Hydraulic cylinders are pivotal in the installation of sheet piles, which are used for flood protection and retaining walls. The controlled force provided by hydraulic systems enables precise placement and alignment of sheet piles, ensuring structural integrity.

6. Challenges and Solutions in Hydraulic Cylinder Technology

As with any technology, hydraulic cylinders face several challenges, including wear and tear, fluid leakage, and maintenance complexities. Manufacturers are addressing these issues through innovative designs and materials that enhance performance and reliability, thereby reducing downtime and maintenance costs.

7. Future Trends in Hydraulic Cylinder Design

Looking ahead, several trends are shaping the future of hydraulic cylinder design. These include greater integration of IoT technologies for enhanced monitoring and control, the development of lightweight materials to improve fuel efficiency, and ongoing innovations in eco-friendly hydraulic fluids.

8. Conclusion

Innovative hydraulic cylinder technologies are revolutionizing the capabilities of pile machinery in the construction industry. By enhancing efficiency, reliability, and sustainability, these advancements are not only meeting the current demands of construction projects but are also paving the way for future innovations. As the industry continues to evolve, embracing these technologies will be crucial for staying competitive and meeting the challenges of tomorrow.

9. Frequently Asked Questions (FAQs)

1. What are hydraulic cylinders used for in pile machinery?

Hydraulic cylinders are used to generate the force necessary for driving piles into the ground, lifting heavy equipment, and performing other critical functions in construction.

2. How do smart hydraulic cylinders improve performance?

Smart hydraulic cylinders utilize sensors to monitor their performance, allowing for real-time data analysis, proactive maintenance, and improved operational efficiency.

3. What are the benefits of eco-friendly hydraulic solutions?

Eco-friendly hydraulic solutions reduce environmental impact through the use of biodegradable fluids and sustainable materials, helping companies meet regulatory compliance and sustainability goals.

4. How can hydraulic cylinders be made more durable?

The durability of hydraulic cylinders can be enhanced through advanced materials, improved sealing technologies, and surface treatments designed to withstand harsh conditions.

5. What future trends should we expect in hydraulic cylinder technology?

Future trends include greater IoT integration, lightweight materials for improved efficiency, and continuous advancements in eco-friendly hydraulic fluids.

Questions?

We are here to help.