Understanding the Components of Hydraulic Cylinders for Mine Machinery

2025-09-10

Understanding the Components of Hydraulic Cylinders for Mine Machinery

Table of Contents

1. Introduction to Hydraulic Cylinders in Mining

2. The Role of Hydraulic Systems in Mine Machinery

3. Key Components of Hydraulic Cylinders

3.1 Cylinder Barrel

3.2 Piston

3.3 Piston Rod

3.4 Seals and Gaskets

3.5 End Caps

4. How Hydraulic Cylinders Work

5. Importance of Hydraulic Cylinders in Mining Operations

6. Maintenance of Hydraulic Cylinders

7. Common Issues and Troubleshooting

8. Future Trends in Hydraulic Technology for Mining

9. FAQs About Hydraulic Cylinders in Mining

10. Conclusion

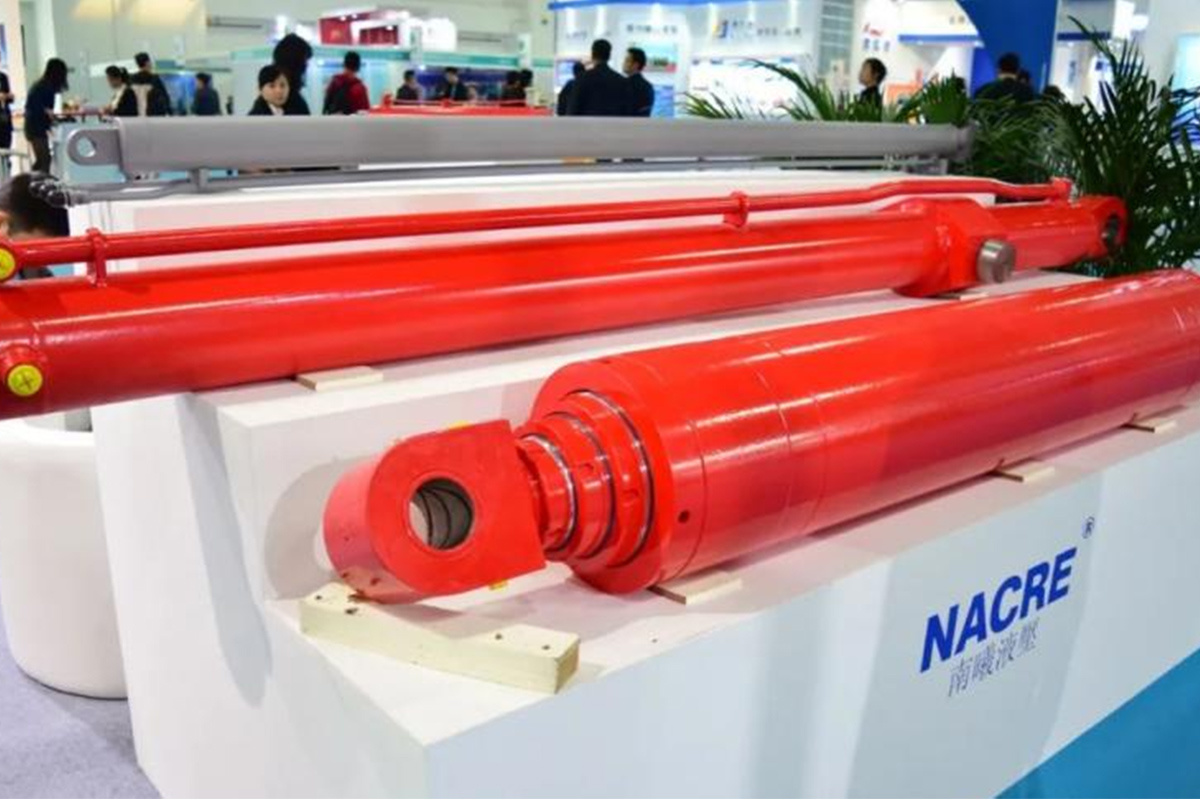

1. Introduction to Hydraulic Cylinders in Mining

Hydraulic cylinders play a pivotal role in the operation of mining machinery, acting as the lifeblood of systems that require heavy lifting and pushing in challenging environments. These components convert hydraulic energy into mechanical energy, facilitating a range of functions, from digging and drilling to transporting materials. This article aims to illuminate the various components of hydraulic cylinders, their significance, and their operational mechanics in the mining sector.

2. The Role of Hydraulic Systems in Mine Machinery

In mining, efficiency and power are paramount. Hydraulic systems are designed to harness the power of pressurized fluid to execute tasks that would be impossible or impractical using mechanical systems alone. The adaptability of hydraulic systems makes them ideal for the dynamic nature of mining operations, where machinery must respond quickly to varying demands.

3. Key Components of Hydraulic Cylinders

Understanding the intricate components of hydraulic cylinders is crucial for anyone involved in the mining industry. Here, we will dissect the primary elements that make up these cylinders.

3.1 Cylinder Barrel

The cylinder barrel is the main body of the hydraulic cylinder. It houses the piston and provides a sealed environment for hydraulic fluid. Made of robust materials, the barrel withstands high pressure and wear, ensuring longevity and reliability.

3.2 Piston

The piston is a critical element that moves back and forth within the cylinder barrel. It is responsible for transferring the hydraulic energy to mechanical energy. Designed for precision, the piston must fit snugly within the barrel to prevent fluid leaks and maintain efficiency.

3.3 Piston Rod

Connected to the piston, the piston rod extends out of the cylinder. It is the component that interacts with other machine parts, converting the hydraulic force into physical movement. The strength and durability of the piston rod are essential for withstanding the stresses encountered during operation.

3.4 Seals and Gaskets

Seals and gaskets are vital for maintaining a leak-free system. They prevent hydraulic fluid from escaping and contaminants from entering the cylinder. High-quality seals are essential for minimizing maintenance needs and ensuring the reliable operation of hydraulic systems.

3.5 End Caps

End caps seal off the ends of the hydraulic cylinder, holding the internal components securely in place. They contribute to the overall structural integrity of the hydraulic system, ensuring that the pressure remains contained within the cylinder.

4. How Hydraulic Cylinders Work

Hydraulic cylinders operate on the principles of fluid mechanics. When hydraulic fluid is pumped into one side of the cylinder, it creates pressure that pushes the piston, causing it to move. This movement can be linear or rotary, depending on the design and application of the hydraulic system. The efficiency of this process relies on the seamless interaction of the components discussed above.

5. Importance of Hydraulic Cylinders in Mining Operations

The importance of hydraulic cylinders in mining cannot be overstated. They facilitate heavy lifting, increase the speed of operations, and improve the safety of mining activities. Whether it’s for excavating, transporting materials, or controlling drilling equipment, hydraulic cylinders enhance productivity and efficiency across the board.

6. Maintenance of Hydraulic Cylinders

To ensure the longevity and efficiency of hydraulic cylinders, regular maintenance is paramount. This includes routine inspections, fluid checks, and seal replacements. Operators must be vigilant about signs of wear and tear, such as leaks or unusual noises, which may indicate a need for immediate attention.

7. Common Issues and Troubleshooting

Common issues with hydraulic cylinders can include leaks, sticking pistons, and unresponsive operations. Troubleshooting these problems is essential for minimizing downtime. Regular maintenance and prompt repairs can often rectify these issues before they lead to significant failures.

8. Future Trends in Hydraulic Technology for Mining

As technology evolves, so too does the field of hydraulic systems. Innovations such as smart hydraulics, which utilize sensors and data analytics, promise to improve efficiency and reduce maintenance costs. Understanding these trends is vital for professionals aiming to stay ahead in the industry.

9. FAQs About Hydraulic Cylinders in Mining

What is the primary function of hydraulic cylinders in mining machinery?

Hydraulic cylinders convert hydraulic energy into mechanical motion, facilitating tasks such as lifting, pushing, and controlling machinery.

How can I tell if my hydraulic cylinder needs maintenance?

Signs of needed maintenance include fluid leaks, unusual noises, or decreased performance. Regular inspections can help identify issues early.

What materials are typically used in hydraulic cylinders?

Hydraulic cylinders are often made from durable metals like steel or aluminum, designed to withstand high pressure and harsh environments.

Can hydraulic cylinders be repaired or do they need to be replaced?

Many hydraulic cylinders can be repaired if the damage is not extensive. However, severe damage may necessitate a complete replacement.

What advancements are being made in hydraulic technology?

Emerging trends include the integration of smart technology, such as sensors that monitor performance and optimize efficiency in real-time.

10. Conclusion

Understanding the components and functions of hydraulic cylinders in mine machinery is crucial for enhancing operational efficiency and safety. By familiarizing ourselves with each component's role, we can better appreciate the complexity and importance of hydraulic systems in mining. Regular maintenance and staying updated on technological advancements will ensure that we continue to maximize productivity in this demanding industry. Embracing these elements not only increases machinery longevity but also propels the mining sector into a more efficient and innovative future.

Questions?

We are here to help.