Understanding Tractor Hydraulic Cylinders: Essential Components for Optimal Performance

2025-09-13

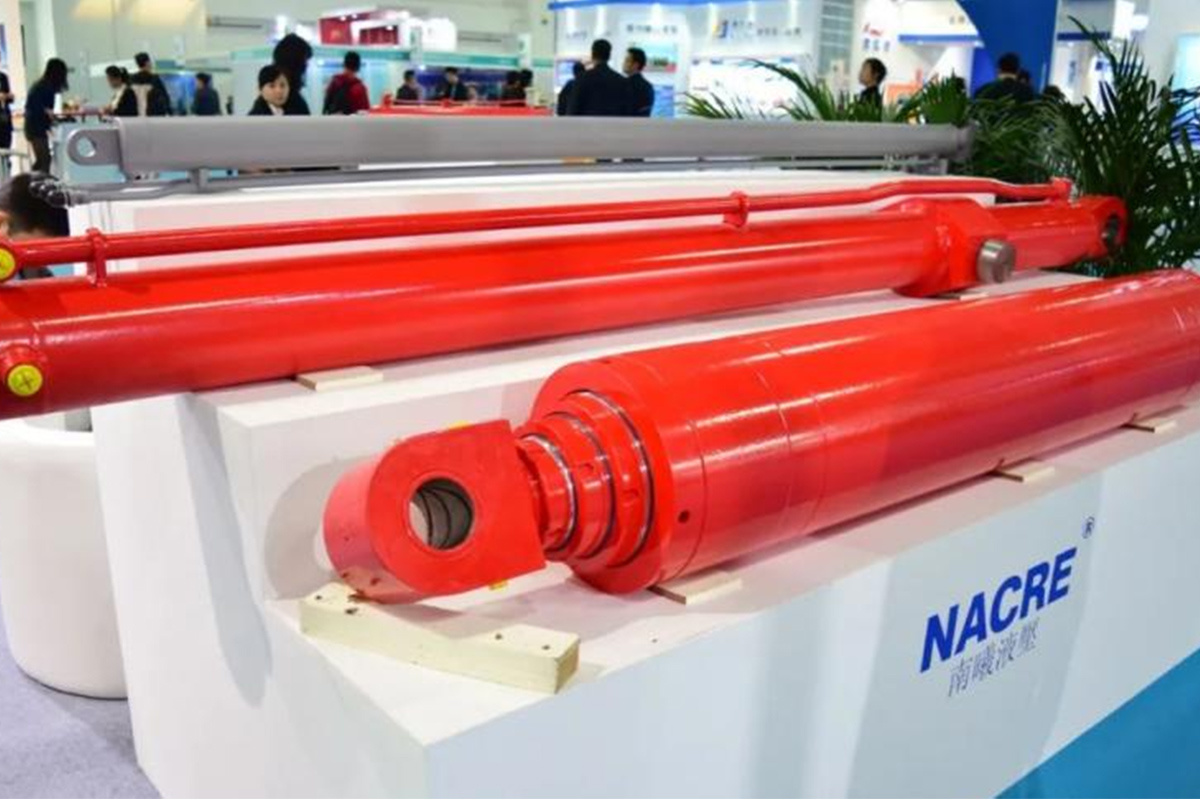

Hydraulic cylinders are integral components in tractors, serving as the driving force that enables various essential functions, such as lifting, steering, and tilting. A tractor hydraulic cylinder converts hydraulic energy into mechanical energy, allowing for efficient operation of implements and attachments that enhance productivity in agricultural tasks. Understanding the intricacies of these hydraulic systems can help professionals optimize their machinery's performance and longevity.

The primary function of a tractor hydraulic cylinder is to generate linear motion through the application of hydraulic pressure. These cylinders are typically composed of several key components: the cylinder barrel, piston, seals, and end caps. The design of these elements is crucial, as it influences the cylinder's efficiency, power output, and overall durability. When selecting a hydraulic cylinder, it is important to consider factors such as stroke length, bore size, and operating pressure to ensure compatibility with the specific requirements of the tractor and its applications.

In addition to design considerations, proper maintenance of tractor hydraulic cylinders is essential for avoiding costly breakdowns. Regular inspections should be conducted to check for signs of wear, leaks, and contamination. Common issues include seal degradation, which can lead to hydraulic fluid leakage, and piston wear, which may result in reduced performance. Implementing a routine maintenance schedule that includes cleaning, lubrication, and timely replacement of worn components can greatly enhance the reliability of hydraulic systems.

Moreover, understanding the role of hydraulic fluid is vital for maximizing the efficiency of tractor hydraulic cylinders. The choice of hydraulic fluid can impact the system's temperature, lubrication properties, and overall performance. It is critical to use fluids that meet the specifications outlined by the manufacturer and to monitor fluid levels regularly to ensure optimal operation.

As technology continues to evolve, advancements in hydraulic cylinder design and materials have led to increased efficiency and reduced environmental impact. Innovations such as integrated sensors for monitoring cylinder performance and smart hydraulic systems that adjust pressure based on load conditions are becoming more common. Staying informed about these developments can empower professionals in the industrial equipment sector to make informed decisions regarding their hydraulic machinery.

In summary, tractor hydraulic cylinders are pivotal for the effective operation of tractors in agricultural settings. By understanding their design, functionality, and maintenance requirements, professionals can enhance the performance and lifespan of their hydraulic systems. Emphasizing the importance of regular maintenance, proper fluid selection, and staying abreast of technological advancements can contribute significantly to operational success in the field.

The primary function of a tractor hydraulic cylinder is to generate linear motion through the application of hydraulic pressure. These cylinders are typically composed of several key components: the cylinder barrel, piston, seals, and end caps. The design of these elements is crucial, as it influences the cylinder's efficiency, power output, and overall durability. When selecting a hydraulic cylinder, it is important to consider factors such as stroke length, bore size, and operating pressure to ensure compatibility with the specific requirements of the tractor and its applications.

In addition to design considerations, proper maintenance of tractor hydraulic cylinders is essential for avoiding costly breakdowns. Regular inspections should be conducted to check for signs of wear, leaks, and contamination. Common issues include seal degradation, which can lead to hydraulic fluid leakage, and piston wear, which may result in reduced performance. Implementing a routine maintenance schedule that includes cleaning, lubrication, and timely replacement of worn components can greatly enhance the reliability of hydraulic systems.

Moreover, understanding the role of hydraulic fluid is vital for maximizing the efficiency of tractor hydraulic cylinders. The choice of hydraulic fluid can impact the system's temperature, lubrication properties, and overall performance. It is critical to use fluids that meet the specifications outlined by the manufacturer and to monitor fluid levels regularly to ensure optimal operation.

As technology continues to evolve, advancements in hydraulic cylinder design and materials have led to increased efficiency and reduced environmental impact. Innovations such as integrated sensors for monitoring cylinder performance and smart hydraulic systems that adjust pressure based on load conditions are becoming more common. Staying informed about these developments can empower professionals in the industrial equipment sector to make informed decisions regarding their hydraulic machinery.

In summary, tractor hydraulic cylinders are pivotal for the effective operation of tractors in agricultural settings. By understanding their design, functionality, and maintenance requirements, professionals can enhance the performance and lifespan of their hydraulic systems. Emphasizing the importance of regular maintenance, proper fluid selection, and staying abreast of technological advancements can contribute significantly to operational success in the field.

Previous Page

Previous Page

Questions?

We are here to help.