Understanding Maritime Port Hydraulic Cylinders: Essential Insights for Industrial Professionals

2025-09-07

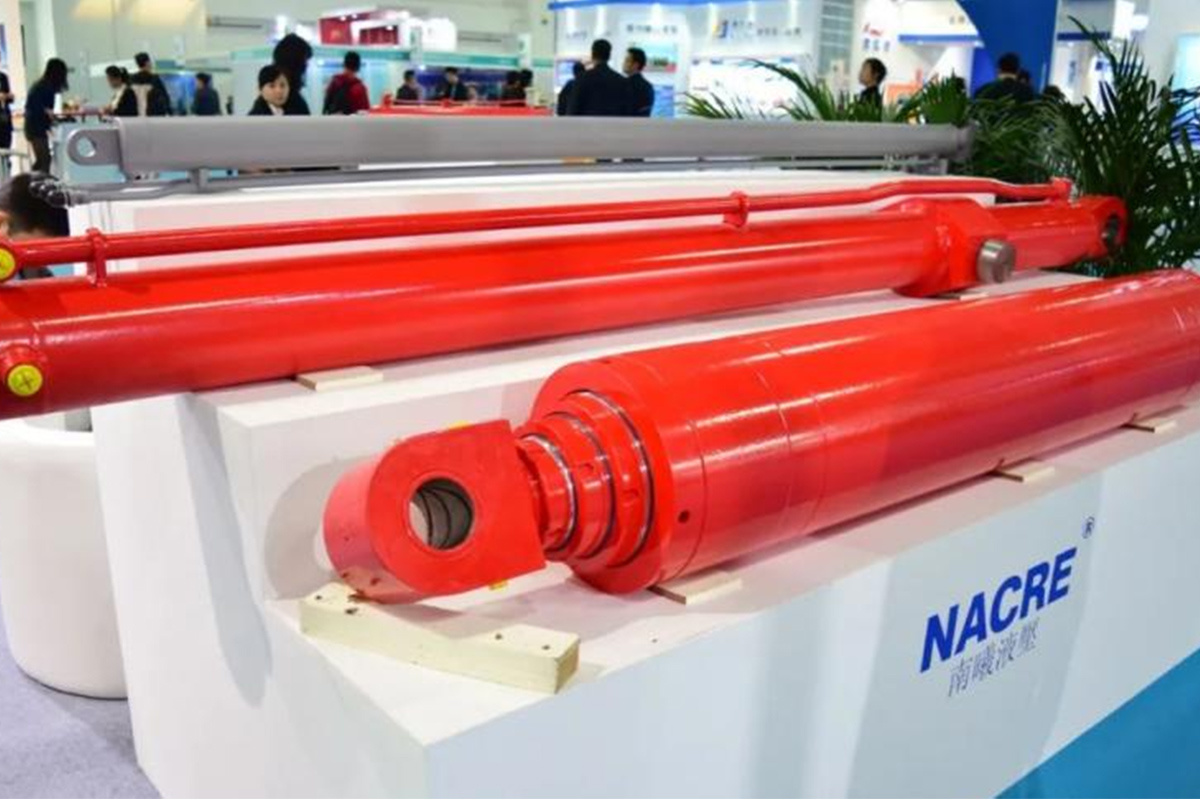

Maritime port hydraulic cylinders play a central role in the effective management and operation of port facilities. These hydraulic components are crucial for various applications, including loading and unloading cargo, operating cranes, and controlling various mechanical systems within the port environment. Understanding the functionality, design, and maintenance of hydraulic cylinders is essential for professionals in the industrial equipment and hydraulic systems sector.

Hydraulic cylinders work on the principle of Pascal's law, where pressure applied to a confined fluid results in force transmission. In maritime ports, these cylinders are typically used to power heavy machinery that operates in a demanding and often challenging environment. The robust design of maritime port hydraulic cylinders ensures they can withstand the harsh marine conditions, including exposure to saltwater, heavy loads, and continuous operation.

One of the primary applications of hydraulic cylinders in maritime ports is in the operation of container handling equipment. These cylinders facilitate the lifting and lowering of containers, enabling efficient transfer between ships and the dock. Additionally, they are integral to the operation of various types of cranes, allowing for precise movement and positioning of heavy loads. The efficiency of port operations relies heavily on the optimal performance of these hydraulic systems.

When selecting maritime port hydraulic cylinders, several factors must be considered. The operating pressure, stroke length, and mounting configurations are essential parameters that directly affect the performance of these cylinders. Professionals in the industry should be well-acquainted with these specifications to ensure they choose the right hydraulic cylinders for their specific applications.

Maintenance and regular inspections of hydraulic cylinders are also critical to ensuring long-term functionality and safety. Common issues such as leaks, wear and tear, and contamination can significantly impact the performance of hydraulic systems. Implementing a proactive maintenance schedule can help identify potential issues before they escalate, thus saving time and costs associated with unexpected downtime.

In summary, maritime port hydraulic cylinders are indispensable components in the logistics and operational efficiency of port facilities. Their importance cannot be overstated, as they enable the smooth handling of cargo and the operation of heavy machinery. Understanding their functionality, applications, and maintenance is crucial for industrial professionals aiming to optimize performance and reliability in maritime environments. By prioritizing the quality and maintenance of hydraulic cylinders, professionals can enhance operational efficiency and contribute to the overall success of port operations.

Hydraulic cylinders work on the principle of Pascal's law, where pressure applied to a confined fluid results in force transmission. In maritime ports, these cylinders are typically used to power heavy machinery that operates in a demanding and often challenging environment. The robust design of maritime port hydraulic cylinders ensures they can withstand the harsh marine conditions, including exposure to saltwater, heavy loads, and continuous operation.

One of the primary applications of hydraulic cylinders in maritime ports is in the operation of container handling equipment. These cylinders facilitate the lifting and lowering of containers, enabling efficient transfer between ships and the dock. Additionally, they are integral to the operation of various types of cranes, allowing for precise movement and positioning of heavy loads. The efficiency of port operations relies heavily on the optimal performance of these hydraulic systems.

When selecting maritime port hydraulic cylinders, several factors must be considered. The operating pressure, stroke length, and mounting configurations are essential parameters that directly affect the performance of these cylinders. Professionals in the industry should be well-acquainted with these specifications to ensure they choose the right hydraulic cylinders for their specific applications.

Maintenance and regular inspections of hydraulic cylinders are also critical to ensuring long-term functionality and safety. Common issues such as leaks, wear and tear, and contamination can significantly impact the performance of hydraulic systems. Implementing a proactive maintenance schedule can help identify potential issues before they escalate, thus saving time and costs associated with unexpected downtime.

In summary, maritime port hydraulic cylinders are indispensable components in the logistics and operational efficiency of port facilities. Their importance cannot be overstated, as they enable the smooth handling of cargo and the operation of heavy machinery. Understanding their functionality, applications, and maintenance is crucial for industrial professionals aiming to optimize performance and reliability in maritime environments. By prioritizing the quality and maintenance of hydraulic cylinders, professionals can enhance operational efficiency and contribute to the overall success of port operations.

Questions?

We are here to help.