How to Extend the Lifespan of Your Excavator Cylinders: Essential Maintenance and Care Tips

2025-09-16

How to Extend the Lifespan of Your Excavator Cylinders: Essential Maintenance and Care Tips

Table of Contents

- Understanding Excavator Cylinders

- Signs of Wear and Tear

- Importance of Regular Maintenance

- Daily Inspection Tips for Excavator Cylinders

- Proper Hydraulic Fluid Management

- Sealing Systems and Their Care

- Troubleshooting Common Issues

- When to Call an Expert

- Conclusion

- FAQs

Understanding Excavator Cylinders

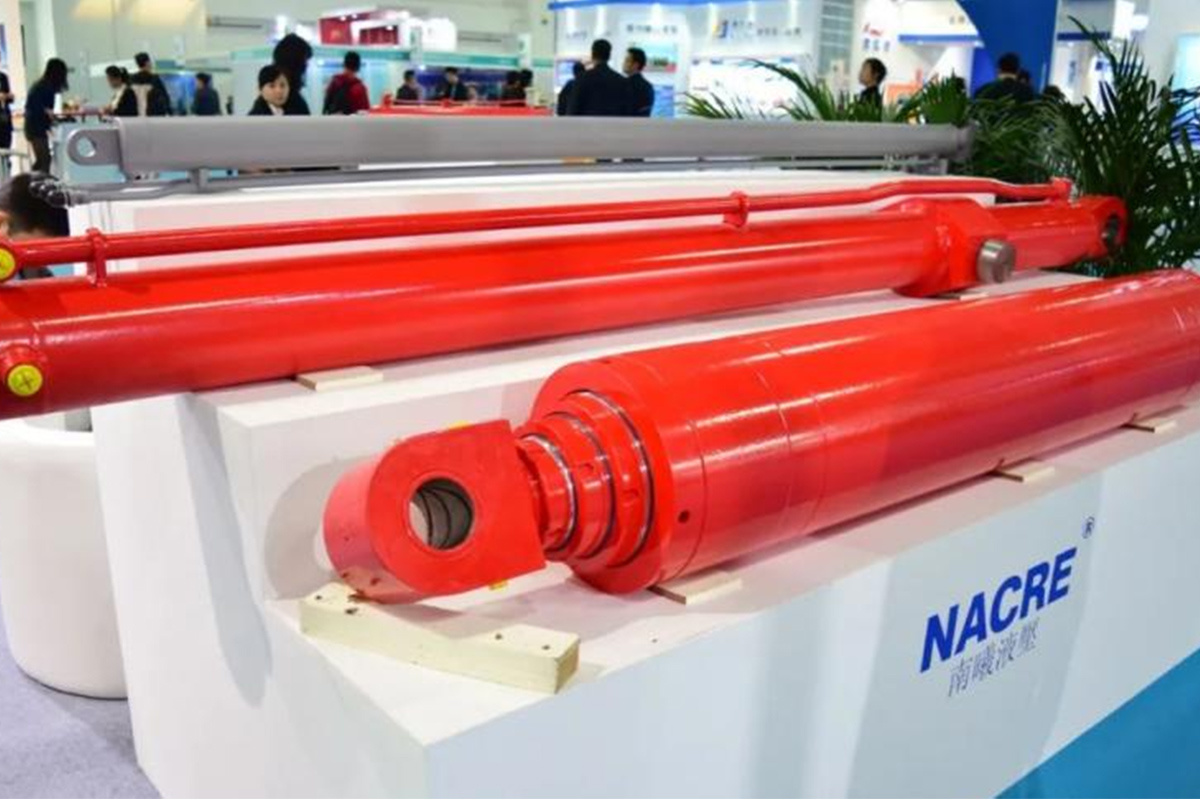

Excavator cylinders play a critical role in the overall functionality of hydraulic excavators. These cylinders convert hydraulic energy into mechanical energy, allowing the machinery to perform various tasks, from digging to lifting. They consist of a barrel, piston, and various seals that work together to create a reliable and efficient movement system. Understanding their design and function is the first step toward extending their lifespan.

Signs of Wear and Tear

Recognizing the early signs of wear and tear is crucial for maintaining the longevity of your excavator cylinders. Common indicators include:

1. Oil Leaks

Oil leaks around the seals or from the cylinder body can signify that the seals are failing or that the cylinder is damaged. Addressing leaks immediately can prevent further damage and costly repairs.

2. Sluggish Operation

If your excavator cylinders operate sluggishly or inconsistently, it may indicate a problem with the hydraulic system or internal wear in the cylinders themselves.

3. Unusual Noises

Grinding, hissing, or knocking sounds during operation are strong indicators of internal issues. These noises often signify worn components that may need immediate attention.

4. Uneven Movement

If the boom or arm of the excavator does not move smoothly or consistently, this could suggest that one or more cylinders are experiencing problems.

Importance of Regular Maintenance

Regular maintenance of excavator cylinders is essential for ensuring their longevity and optimal performance. By committing to a routine maintenance schedule, operators can identify potential issues before they escalate, thereby reducing downtime and repair costs.

1. Cost Savings

Investing time and resources into preventive maintenance can save significant costs in the long run. By avoiding major repairs and replacements, you can keep your equipment running efficiently.

2. Enhanced Performance

Well-maintained cylinders operate more efficiently, leading to improved performance of the entire excavator. This efficiency translates to increased productivity on job sites.

3. Safety Assurance

Faulty cylinders can lead to catastrophic failures, posing safety risks to operators and other workers on-site. Regular checks and maintenance help ensure safe operation.

Daily Inspection Tips for Excavator Cylinders

Conducting daily inspections of your excavator cylinders is a crucial part of a comprehensive maintenance plan. Here are some tips to help you perform effective daily inspections:

1. Visual Checks

Inspect the cylinders for any visible signs of damage, such as dents, scrapes, or rust. Pay close attention to the seals and rods for any signs of wear.

2. Check for Leaks

Look for any signs of hydraulic fluid leaks. If you notice oil on the ground or around the cylinder, this could indicate a problem that needs immediate attention.

3. Test Functionality

Operate the excavator to test the functionality of the cylinders. Ensure that they move smoothly and respond promptly to control inputs.

4. Monitor Fluid Levels

Check the hydraulic fluid levels daily. Low fluid levels can lead to insufficient lubrication and increased wear on cylinder components.

Proper Hydraulic Fluid Management

Hydraulic fluid plays a vital role in the operation and longevity of excavator cylinders. Proper management of hydraulic fluid can significantly extend the life of these components.

1. Choosing the Right Fluid

Select a hydraulic fluid that meets the manufacturer’s specifications. The wrong fluid can lead to poor performance and increased wear on components.

2. Regular Fluid Changes

Follow a routine schedule for changing the hydraulic fluid. Over time, fluid can become contaminated with debris and moisture, which can harm the cylinders.

3. Maintaining Cleanliness

Keep the hydraulic system clean by ensuring that fluid reservoirs and lines are free of dirt and contaminants. Contamination can cause significant damage to cylinder seals and rods.

Sealing Systems and Their Care

The sealing systems on excavator cylinders are crucial for preventing leaks and maintaining pressure. Proper care of these seals is essential for ensuring the longevity of the cylinders.

1. Regular Seal Inspections

Inspect seals regularly for signs of wear or damage. Any fraying or cracking can lead to leaks and reduced performance.

2. Lubrication

Ensure that seals are properly lubricated to reduce friction and wear. Use a lubricant that is compatible with the hydraulic fluid to avoid chemical reactions that could damage the seals.

3. Replace Worn Seals Promptly

If seals show signs of wear, replace them immediately. Delaying seal replacement can lead to more extensive damage to the cylinders.

Troubleshooting Common Issues

Even with regular maintenance, issues can arise with excavator cylinders. Knowing how to troubleshoot common problems can help you address them quickly.

1. Dealing with Oil Leaks

If you discover an oil leak, first identify the source. If it’s from a seal, replace it. If the leak is from the cylinder body, inspect for cracks or damage that may require professional repair.

2. Addressing Sluggish Performance

Sluggish performance often indicates low hydraulic fluid levels or contaminated fluid. Check and top off fluid levels, and consider changing the fluid if it appears dirty.

3. Resolving Noisy Operation

Identify the source of noise during operation. If it’s linked to the cylinders, check for loose fittings or internal wear. Tightening fittings may resolve the noise, but worn parts will need replacement.

When to Call an Expert

While many maintenance tasks can be handled by operators, some issues require the expertise of professionals. Knowing when to call in an expert can save time and prevent further damage.

1. In-Depth Inspections

If you notice persistent issues or abnormal wear patterns, it’s best to seek a professional inspection. Experts can provide insights and solutions that may not be immediately apparent.

2. Complex Repairs

For complex repairs, such as hydraulic cylinder rebuilding or replacement, hiring a professional is advisable. These repairs require specialized knowledge and equipment.

3. Performance Issues

If performance issues persist despite your maintenance efforts, consulting with a hydraulic specialist can help identify underlying problems that may not be visible during regular checks.

Conclusion

Extending the lifespan of your excavator cylinders requires a proactive approach that includes regular inspections, proper maintenance, and a commitment to addressing issues promptly. By implementing the strategies outlined in this guide, you can ensure that your hydraulic cylinders remain in optimal condition, reducing downtime and enhancing productivity on the job site. Remember, a well-maintained excavator not only performs better but also contributes to the safety and efficiency of your operations.

FAQs

1. How often should I inspect my excavator cylinders?

Inspect your excavator cylinders daily during regular use to catch any issues early.

2. What are the main causes of hydraulic cylinder failure?

Common causes include fluid contamination, inadequate lubrication, wear and tear, and improper operation.

3. How can I tell if my hydraulic fluid needs changing?

If the hydraulic fluid appears dark, contains debris, or has a burnt smell, it’s time to change it.

4. Can I replace seals on my own?

If you have the necessary tools and knowledge, you can replace seals, but for complex issues, it may be better to consult a professional.

5. What should I do if I notice a leak?

Identify the source of the leak and address it promptly, whether that means tightening fittings, replacing seals, or seeking professional repair if the issue is more serious.

Previous Page

Previous Page

Questions?

We are here to help.