The Essential Guide to Loader Hydraulic Cylinders: Understanding Their Role and Functionality

2025-09-19

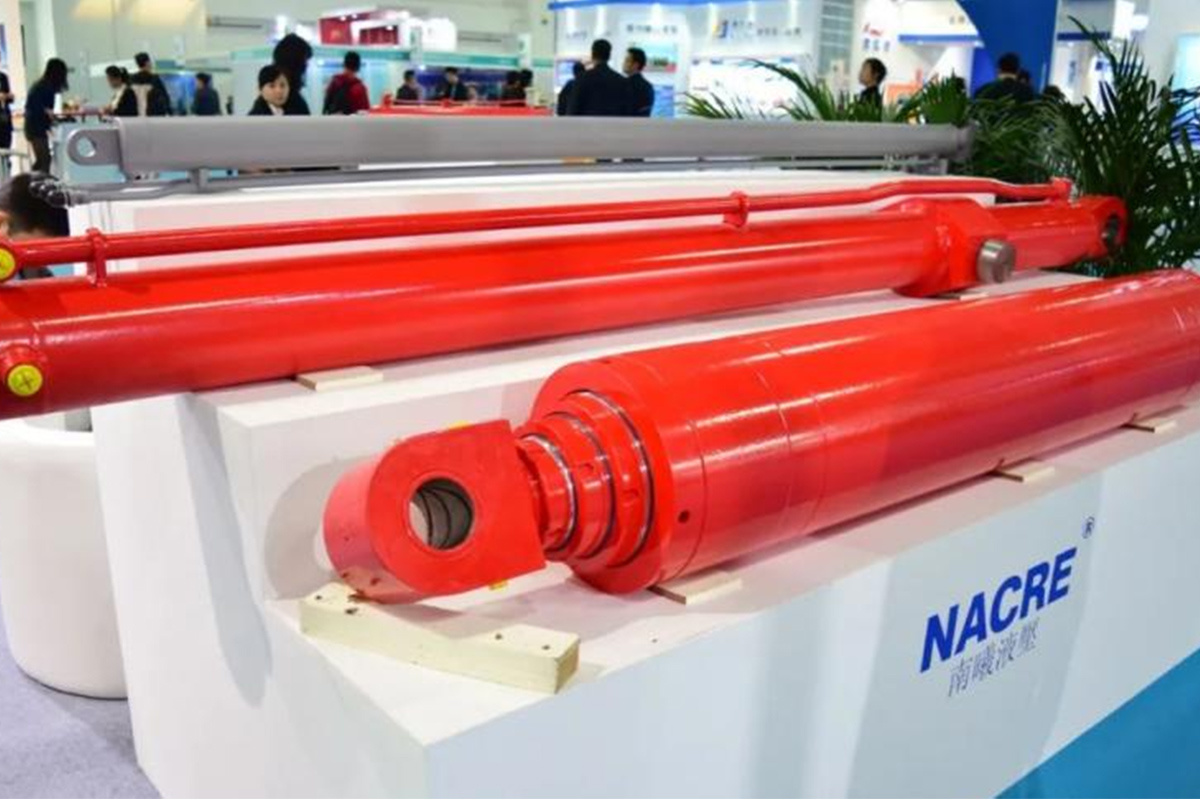

Loader hydraulic cylinders are vital components in various industrial applications, especially within the realm of hydraulic machinery. These cylinders are designed to convert hydraulic energy into mechanical force, enabling loaders to perform heavy lifting and pushing tasks efficiently. Understanding the functionality and applications of loader hydraulic cylinders can help operators maximize their equipment's performance.

At the core of a loader hydraulic cylinder is a simple yet effective design that consists of a cylinder barrel, a piston, and hydraulic fluid. When pressurized hydraulic fluid enters the cylinder, it pushes the piston, which in turn moves the load attached to the loader. The efficiency of this process is critical, as it directly affects the loader's lifting capabilities and speed.

Loader hydraulic cylinders are commonly used in construction and agricultural equipment, where they facilitate the lifting of heavy materials like soil, gravel, and machinery. Their robust design allows them to withstand high pressures and heavy loads, making them indispensable in settings where durability is paramount. Additionally, the ability to control the speed and force of the piston movement provides operators with precision when handling loads, reducing the risk of accidents and damage to equipment.

Maintenance is crucial to ensure the reliable performance of loader hydraulic cylinders. Regular inspections for leaks, wear, and damage can prevent costly downtime and repairs. Operators should keep an eye on hydraulic fluid levels and quality, as degraded fluid can lead to inefficient operation and increased wear on the cylinder components. Lubrication of moving parts and ensuring that seals are intact also play a significant role in extending the lifespan of the hydraulic cylinder.

When selecting a loader hydraulic cylinder, consider the specific requirements of your machinery and the nature of the tasks you’ll be performing. Factors such as load capacity, stroke length, and mounting options are critical to ensure compatibility and optimal performance. It’s also important to understand the environmental conditions in which the cylinder will operate, as extreme temperatures or exposure to contaminants can affect the operation and longevity of the hydraulic system.

In summary, loader hydraulic cylinders are essential for the effective operation of hydraulic machinery in industrial applications. Their ability to provide reliable lifting power, coupled with the importance of regular maintenance, underscores the significance of these components in ensuring operational efficiency. By understanding their functionality and adhering to best practices, operators can maximize the performance and durability of loader hydraulic cylinders in their equipment.

At the core of a loader hydraulic cylinder is a simple yet effective design that consists of a cylinder barrel, a piston, and hydraulic fluid. When pressurized hydraulic fluid enters the cylinder, it pushes the piston, which in turn moves the load attached to the loader. The efficiency of this process is critical, as it directly affects the loader's lifting capabilities and speed.

Loader hydraulic cylinders are commonly used in construction and agricultural equipment, where they facilitate the lifting of heavy materials like soil, gravel, and machinery. Their robust design allows them to withstand high pressures and heavy loads, making them indispensable in settings where durability is paramount. Additionally, the ability to control the speed and force of the piston movement provides operators with precision when handling loads, reducing the risk of accidents and damage to equipment.

Maintenance is crucial to ensure the reliable performance of loader hydraulic cylinders. Regular inspections for leaks, wear, and damage can prevent costly downtime and repairs. Operators should keep an eye on hydraulic fluid levels and quality, as degraded fluid can lead to inefficient operation and increased wear on the cylinder components. Lubrication of moving parts and ensuring that seals are intact also play a significant role in extending the lifespan of the hydraulic cylinder.

When selecting a loader hydraulic cylinder, consider the specific requirements of your machinery and the nature of the tasks you’ll be performing. Factors such as load capacity, stroke length, and mounting options are critical to ensure compatibility and optimal performance. It’s also important to understand the environmental conditions in which the cylinder will operate, as extreme temperatures or exposure to contaminants can affect the operation and longevity of the hydraulic system.

In summary, loader hydraulic cylinders are essential for the effective operation of hydraulic machinery in industrial applications. Their ability to provide reliable lifting power, coupled with the importance of regular maintenance, underscores the significance of these components in ensuring operational efficiency. By understanding their functionality and adhering to best practices, operators can maximize the performance and durability of loader hydraulic cylinders in their equipment.

Previous Page

Previous Page

Questions?

We are here to help.