The Importance of Maintenance for Tractor Loader Cylinders: Ensuring Longevity and Performance

2025-09-22

The Importance of Maintenance for Tractor Loader Cylinders

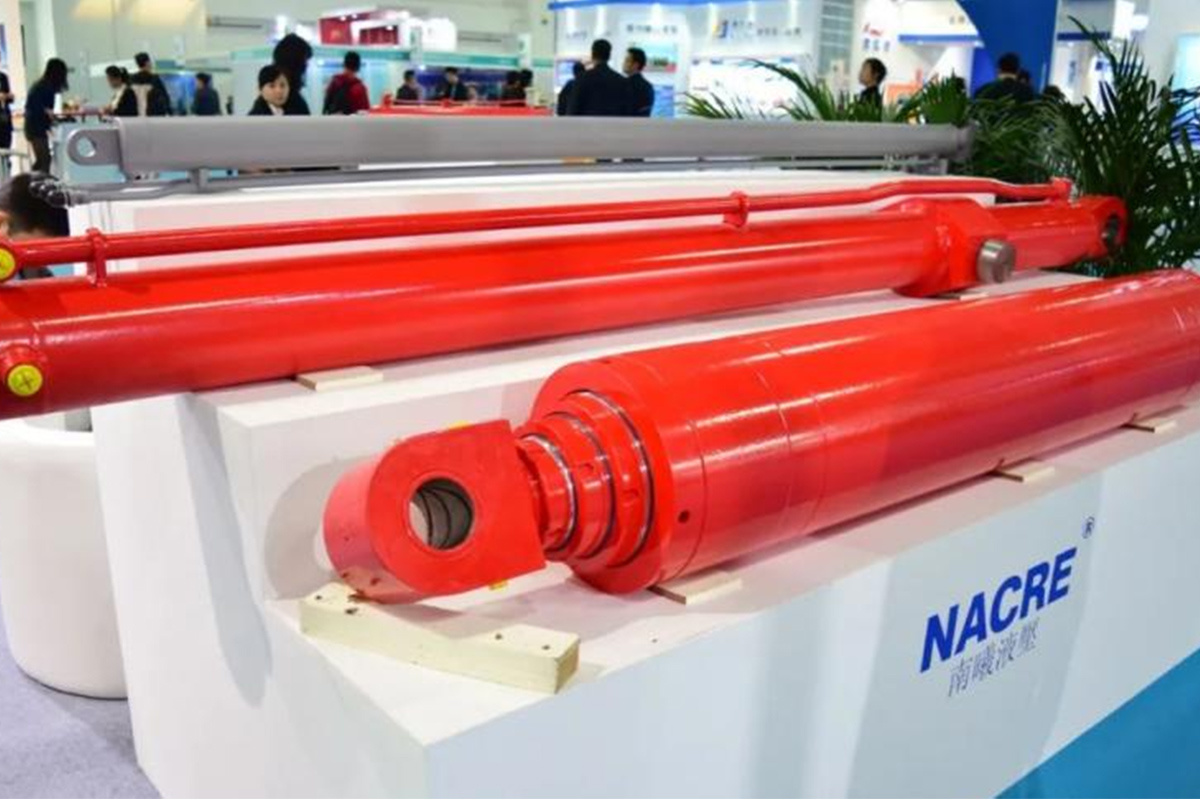

Understanding Tractor Loader Cylinders

Tractor loader cylinders play a pivotal role in the operation of hydraulic machinery. These cylinders are designed to convert hydraulic energy into mechanical force, enabling the lifting and moving of heavy loads with efficiency. The importance of these components cannot be overstated; they are essential for the functionality of various agricultural, construction, and industrial tasks.

Why Regular Maintenance is Crucial

Regular maintenance of tractor loader cylinders is vital for several reasons:

1. Enhancing Performance

Consistent maintenance ensures that your cylinders operate at peak efficiency. Lubrication, inspection, and timely repairs help maintain optimal performance levels, allowing for smoother operation and better productivity.

2. Preventing Costly Breakdowns

Failure to maintain tractor loader cylinders can lead to mechanical failures that are often expensive to repair. Regular checks can catch potential issues before they escalate, ultimately saving money and reducing downtime.

3. Extending Equipment Lifespan

Well-maintained cylinders can significantly extend the lifespan of your equipment. By following a structured maintenance schedule, operators can ensure that their loaders remain functional for years to come, maximizing their investment.

Key Maintenance Practices for Tractor Loader Cylinders

To ensure the longevity and reliability of tractor loader cylinders, it is essential to implement a comprehensive maintenance routine. Here are some fundamental practices to incorporate:

1. Regular Inspection

Conducting frequent inspections of tractor loader cylinders is crucial. Look for signs of wear, leaks, and damage. Early detection of issues can prevent more severe problems down the line.

Visual Checks

Start with a visual inspection. Look for any rust, corrosion, or physical damage on the cylinders. Ensure that all fittings and seals are intact and free from wear.

Performance Monitoring

Monitor the performance of the cylinders during operation. Any irregular sounds or performance issues should be addressed immediately.

2. Proper Lubrication

Lubrication is vital for reducing friction and wear in hydraulic cylinders. Ensure that the correct type and amount of lubricant are applied regularly.

Choosing the Right Lubricant

Select lubricants that are compatible with your hydraulic fluid. Using the wrong lubricant can lead to deterioration of seals and other components.

Lubrication Schedule

Develop a lubrication schedule based on usage frequency and operating conditions. More frequent use or harsher conditions may require more regular lubrication.

3. Seal Maintenance and Replacement

Seals are critical in preventing hydraulic fluid leaks. Inspect seals regularly for signs of wear or damage, and replace them as necessary to maintain proper function.

Types of Seals

Understand the different types of seals used in hydraulic systems, such as O-rings and rod seals, to effectively identify and replace any that are compromised.

Installation Tips

When replacing seals, ensure that the installation is done correctly to prevent leaks and other issues. Use proper tools and techniques to minimize the risk of damage.

4. Hydraulic Fluid Checks

The hydraulic fluid used in tractor loader cylinders plays a critical role in performance. Regularly check the fluid levels and quality.

Fluid Level Monitoring

Maintain the hydraulic fluid at the recommended levels. Low fluid levels can lead to increased wear and potential mechanical failure.

Fluid Quality Assessment

Inspect the hydraulic fluid for contamination and degradation. Change the fluid based on the manufacturer's recommendations or when signs of contamination are evident.

5. Temperature Regulation

Hydraulic cylinders can be sensitive to temperature fluctuations. Monitoring and regulating operating temperature can prevent overheating and consequent damage.

Temperature Checks

Utilize temperature gauges to monitor the hydraulic system's temperature. Any significant increases should be investigated immediately.

Cooling Solutions

Consider implementing cooling systems or heat exchangers to manage temperature and maintain optimal operating conditions.

Common Issues and How to Address Them

Despite proper maintenance, various issues can arise with tractor loader cylinders. Understanding these common problems can help operators address them effectively.

1. Hydraulic Fluid Leaks

Leaks can occur due to worn seals or fittings. Promptly address any leaks to avoid loss of hydraulic pressure and system failure.

2. Reduced Lifting Capacity

If the loader is struggling to lift loads, this could signify internal wear or damage. Inspect the cylinders for any physical damage and consider professional servicing if necessary.

3. Erratic Operation

Inconsistent performance can be indicative of issues with hydraulic fluid quality or system pressure. Ensure the hydraulic fluid is clean and at the correct level.

Benefits of Professional Maintenance Services

While regular maintenance can often be performed by operators, engaging professional services can offer several advantages:

1. Expert Insights

Professionals possess the knowledge and experience to identify potential issues that may not be apparent to the untrained eye. Their expertise can help prevent future problems.

2. Comprehensive Service

Professional services often provide a more thorough inspection and maintenance process, ensuring that all aspects of the hydraulic system are addressed.

3. Time Efficiency

Outsourcing maintenance allows operators to focus on their primary tasks, enhancing overall productivity while ensuring the equipment is in top condition.

DIY Maintenance Tips for Tractor Loader Cylinders

For those who prefer a hands-on approach, here are some **DIY maintenance tips** to keep in mind:

1. Create a Maintenance Log

Keep a detailed record of all maintenance activities, including inspections, fluid changes, and repairs. This log can help track performance and identify patterns over time.

2. Use Quality Parts for Repairs

When replacing parts, always opt for high-quality components to ensure longevity and reliability.

3. Stay Informed

Regularly update yourself with the latest best practices and recommendations for maintaining hydraulic systems. Engaging with professional networks or attending workshops can provide valuable insights.

FAQs About Tractor Loader Cylinder Maintenance

1. How often should I inspect my tractor loader cylinders?

Regular inspections should be performed at least once a month, with more frequent checks if the equipment is used heavily.

2. What type of hydraulic fluid is best for my tractor loader?

Consult the manufacturer's guidelines for the recommended type of hydraulic fluid. Typically, it's best to use fluids specifically formulated for hydraulic systems.

3. Can I replace seals myself?

Yes, seal replacement can be a DIY task, but ensure you follow proper procedures to avoid damaging the cylinder.

4. What are signs that my hydraulic cylinders need professional maintenance?

If you experience persistent leaks, reduced performance, or overheating, it's advisable to seek professional maintenance services.

5. How can I prevent rust on my hydraulic cylinders?

Regular cleaning and lubrication can help prevent rust. Additionally, storing equipment in a dry environment will minimize deterioration.

Conclusion

In summary, the significance of maintenance for tractor loader cylinders cannot be understated. Regular inspections, lubrication, seal maintenance, and hydraulic fluid checks are crucial practices that contribute to the equipment's longevity and performance. By adopting a proactive maintenance approach, operators can enhance efficiency, prevent costly repairs, and ensure that their machinery remains an invaluable asset for years to come. Engaging professionals for more complex tasks can further streamline the process, allowing for optimal operational efficiency.

Previous Page

Previous Page

Questions?

We are here to help.