Understanding Tie Rod Cylinders: A Comprehensive Guide to Hydraulic Cylinders

2025-09-25

---

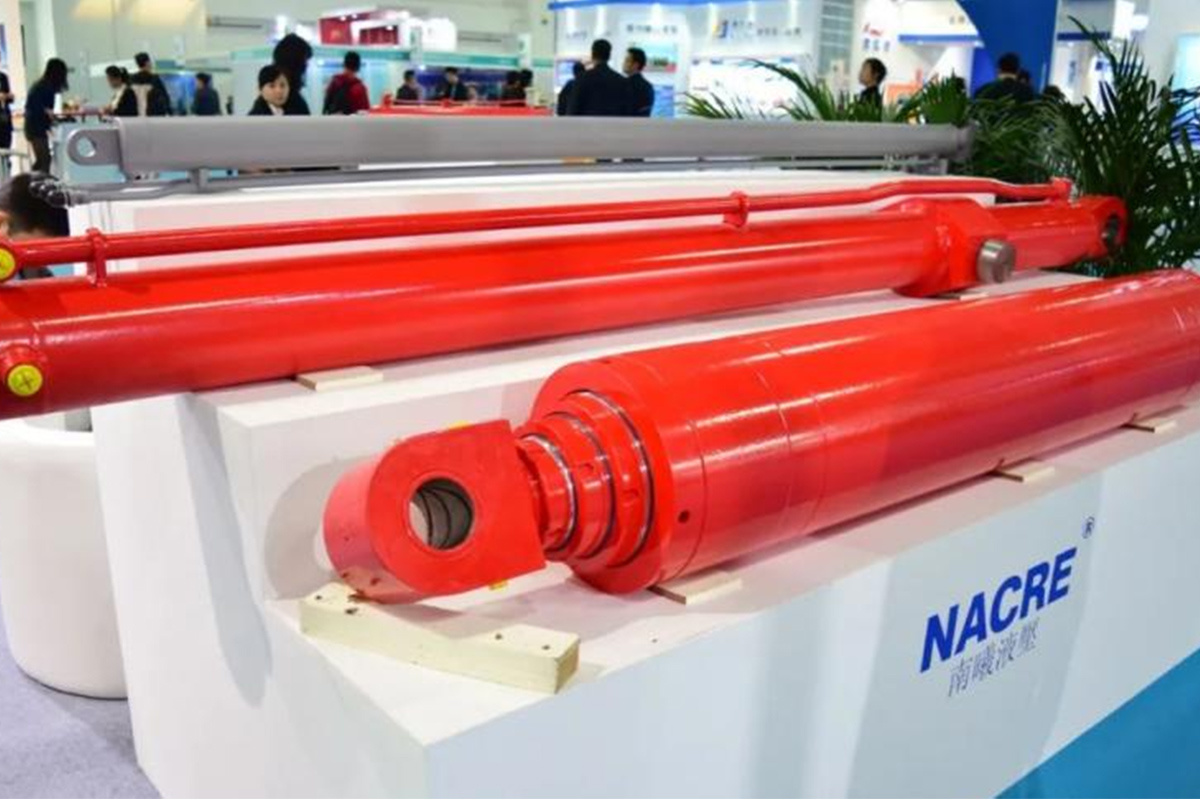

Tie rod cylinders are a vital component in the realm of hydraulic machinery, providing the necessary force and motion for various industrial applications. These cylinders are characterized by their robust design, which typically includes a cylindrical barrel, a piston, and tie rods that hold the assembly together. The tie rods serve to maintain structural integrity under high-pressure conditions, making them suitable for heavy-duty applications.

One of the primary advantages of tie rod cylinders is their adaptability. They are available in various sizes and configurations, allowing them to be customized for specific applications. This versatility means that they can be used in everything from manufacturing machinery to construction equipment, serving functions that require both linear and rotary motion.

The construction of tie rod cylinders typically consists of high-strength materials that can withstand the harsh environments often found in industrial settings. The tie rods, which connect the end caps to the barrel, are crucial for maintaining the alignment of the cylinder and ensuring that it operates efficiently. Properly tensioned tie rods help to prevent leakage and maintain pressure within the system, which is vital for optimal performance.

In terms of maintenance, tie rod cylinders often require periodic inspection to ensure that all components are functioning correctly. Signs of wear, such as leaks around the seals or unusual noises during operation, can indicate that maintenance is needed to avoid costly downtime. Regular maintenance practices may include checking the fluid levels, inspecting for any signs of corrosion, and ensuring that tie rods are properly tightened.

When selecting a tie rod cylinder for a specific application, it is essential to consider the operating pressure, stroke length, and load capacity. Each of these factors will influence the cylinder's performance and suitability for a given task. Additionally, understanding the working environment—such as temperature fluctuations, exposure to chemicals, and potential physical obstructions—can help in selecting the right cylinder configuration.

In conclusion, tie rod cylinders play a critical role in hydraulic systems across a variety of industries. Their robust design, adaptability, and ease of maintenance make them a popular choice for engineers and manufacturers alike. By understanding the functionality and applications of tie rod cylinders, stakeholders can make informed decisions when integrating these essential components into their hydraulic systems. Whether for powering machinery or facilitating intricate movements, tie rod cylinders continue to be a cornerstone in the world of hydraulic mechanisms.

Tie rod cylinders are a vital component in the realm of hydraulic machinery, providing the necessary force and motion for various industrial applications. These cylinders are characterized by their robust design, which typically includes a cylindrical barrel, a piston, and tie rods that hold the assembly together. The tie rods serve to maintain structural integrity under high-pressure conditions, making them suitable for heavy-duty applications.

One of the primary advantages of tie rod cylinders is their adaptability. They are available in various sizes and configurations, allowing them to be customized for specific applications. This versatility means that they can be used in everything from manufacturing machinery to construction equipment, serving functions that require both linear and rotary motion.

The construction of tie rod cylinders typically consists of high-strength materials that can withstand the harsh environments often found in industrial settings. The tie rods, which connect the end caps to the barrel, are crucial for maintaining the alignment of the cylinder and ensuring that it operates efficiently. Properly tensioned tie rods help to prevent leakage and maintain pressure within the system, which is vital for optimal performance.

In terms of maintenance, tie rod cylinders often require periodic inspection to ensure that all components are functioning correctly. Signs of wear, such as leaks around the seals or unusual noises during operation, can indicate that maintenance is needed to avoid costly downtime. Regular maintenance practices may include checking the fluid levels, inspecting for any signs of corrosion, and ensuring that tie rods are properly tightened.

When selecting a tie rod cylinder for a specific application, it is essential to consider the operating pressure, stroke length, and load capacity. Each of these factors will influence the cylinder's performance and suitability for a given task. Additionally, understanding the working environment—such as temperature fluctuations, exposure to chemicals, and potential physical obstructions—can help in selecting the right cylinder configuration.

In conclusion, tie rod cylinders play a critical role in hydraulic systems across a variety of industries. Their robust design, adaptability, and ease of maintenance make them a popular choice for engineers and manufacturers alike. By understanding the functionality and applications of tie rod cylinders, stakeholders can make informed decisions when integrating these essential components into their hydraulic systems. Whether for powering machinery or facilitating intricate movements, tie rod cylinders continue to be a cornerstone in the world of hydraulic mechanisms.

Previous Page

Previous Page

Questions?

We are here to help.